DIAMOND IN THE ROUGH

A good definition to start this post (and all of H.G.'s work IMO) is

Diamond in the rough.

Quoted Text

Someone (or something) that has hidden exceptional characteristics and/or future potential, but currently lacks the final touches that would make them (or it) truly stand out from the crowd.

The phrase is metaphorical and relates to the fact that naturally occurring diamonds are quite ordinary at first glance, and that their true beauty as jewels is only realized through the cutting and polishing process.

That's kind of how I see the collaboration between H.G. and me at this point. I look upon my work as the rough diamond that he is converting into a beautiful jewel.

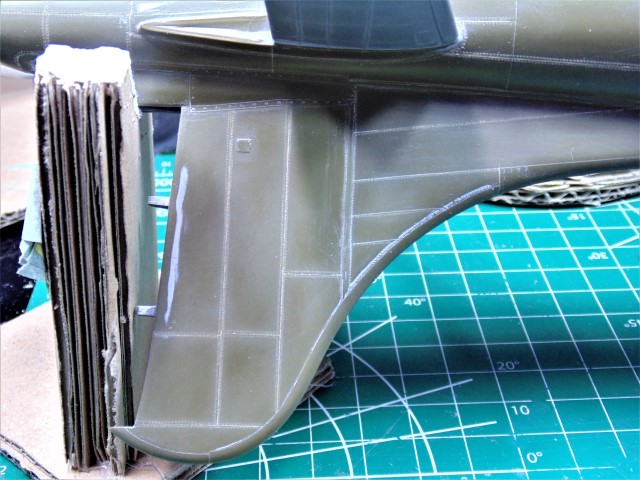

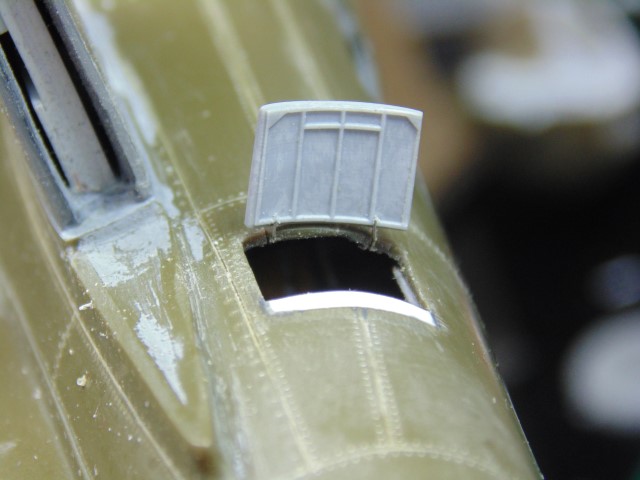

Let's consider the nose crew access/escape hatch for starters.

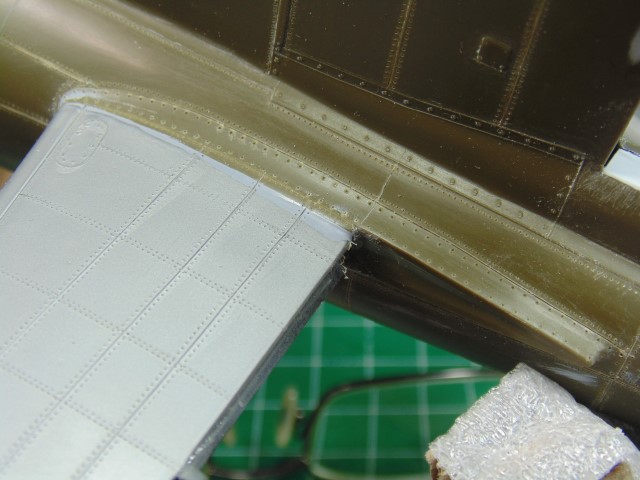

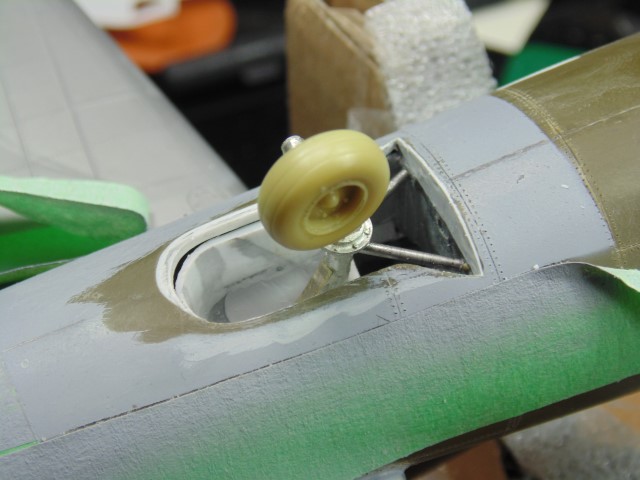

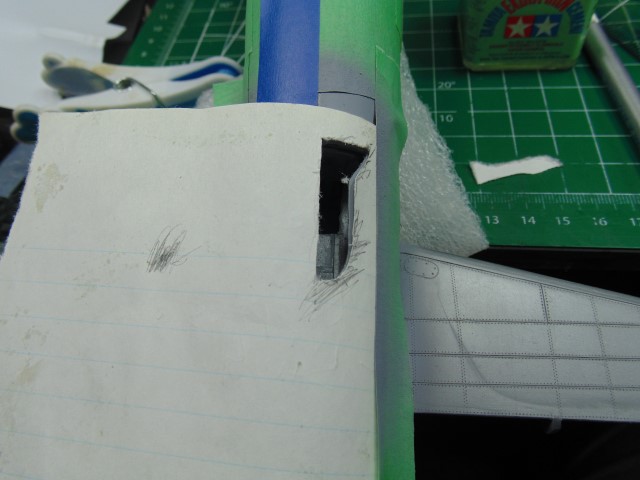

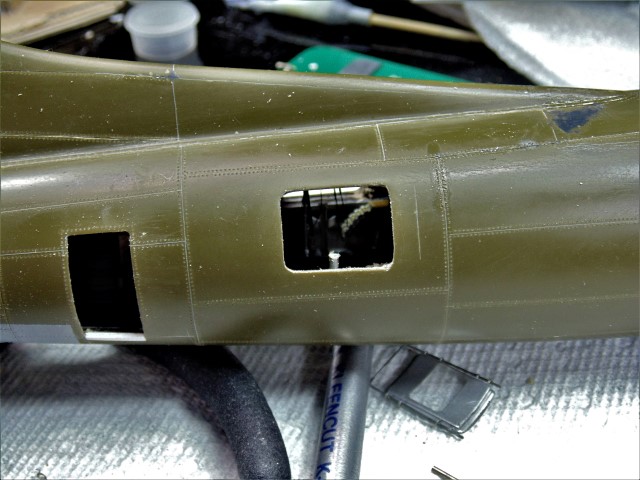

It's worth recalling that when I added the walk/crawlway to the floor leading to the navigator/bombardier compartment door, I added some perpendicular formers to address the gap visible in the open hatch between the walkway and the floor,

similar to those that were in the space behind the door opening. See below, right.

H.G. recognized the need to eliminate the formers and come up with a solution that looks closer to the real thing.

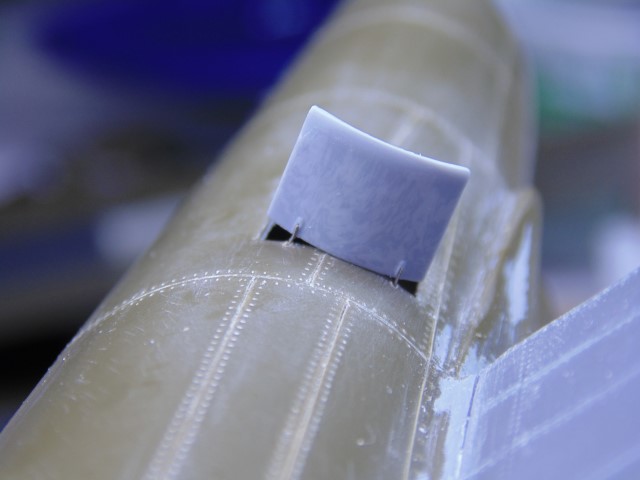

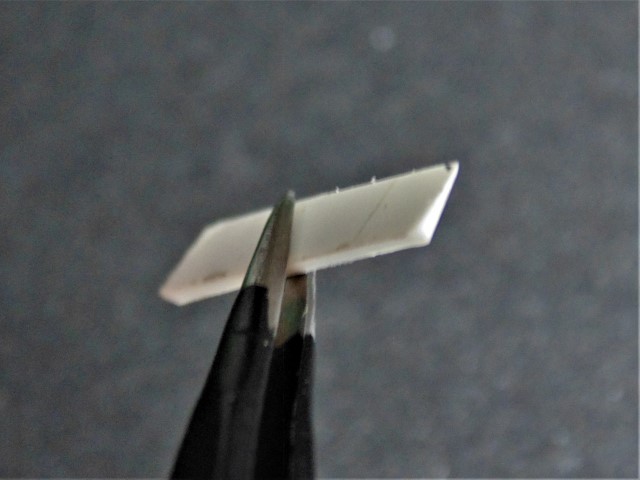

He filled the gap

fashioned a plate to reduce the sense of excessive height

and then inserted it to create a flatter look.

(The small gap near the door opening will be eliminated later.)

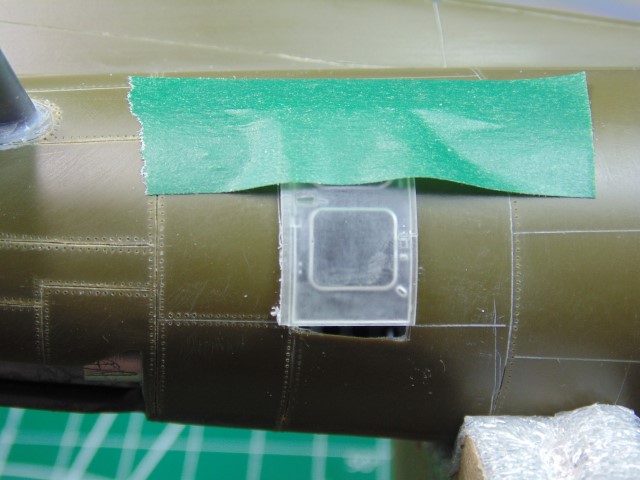

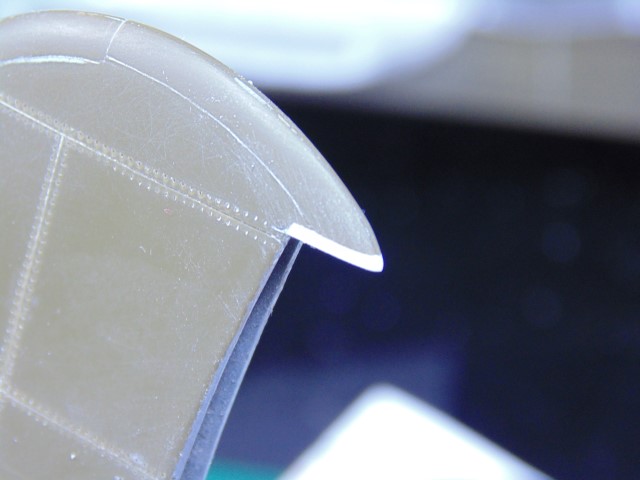

You can also see that the door opening

now matches the door dimensions MUCH better.

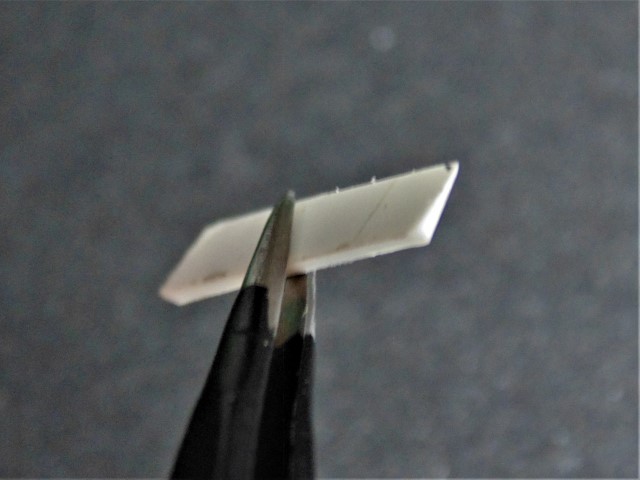

And yes, those are custom-made door hinges.

which will fit the door beautifully.

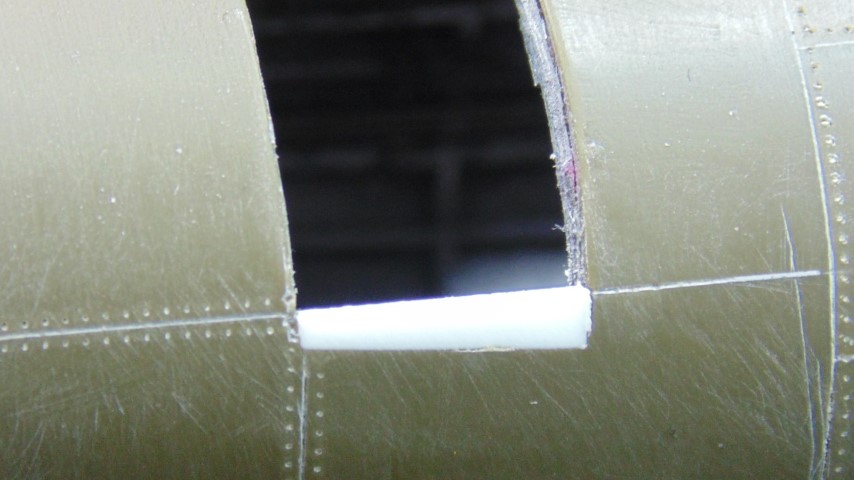

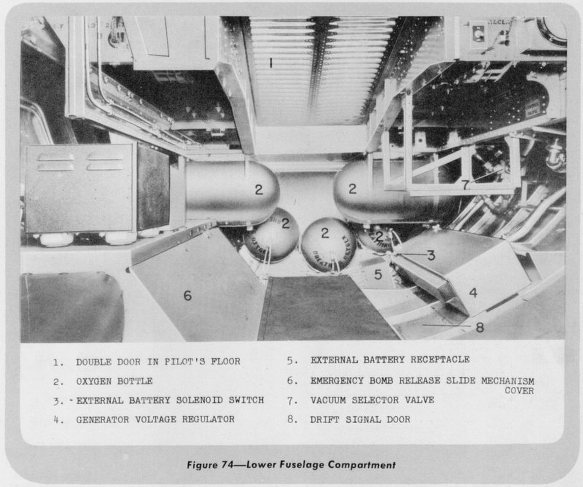

and what's not to like about the model door

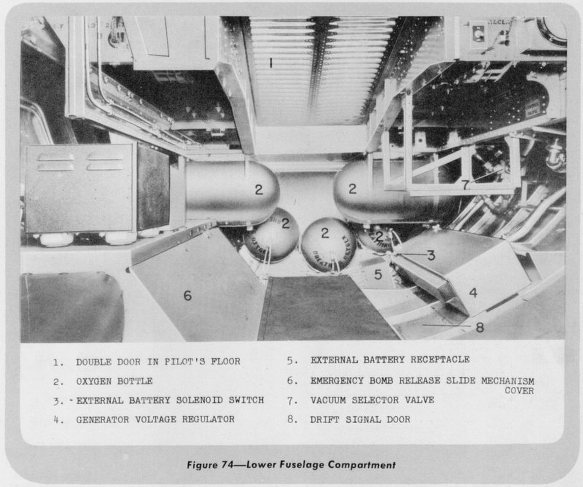

vs. the real thing?

I call this the edge of a beautifully cut diamond!

_________________________________________________________________

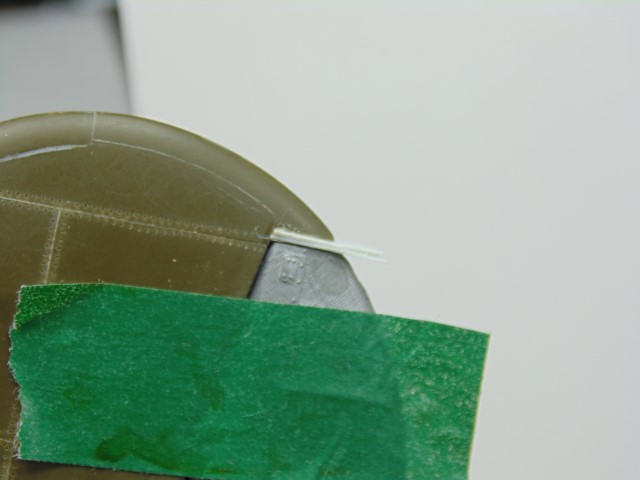

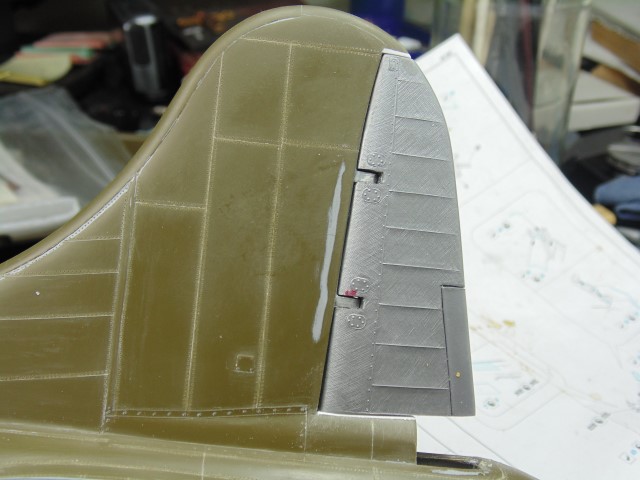

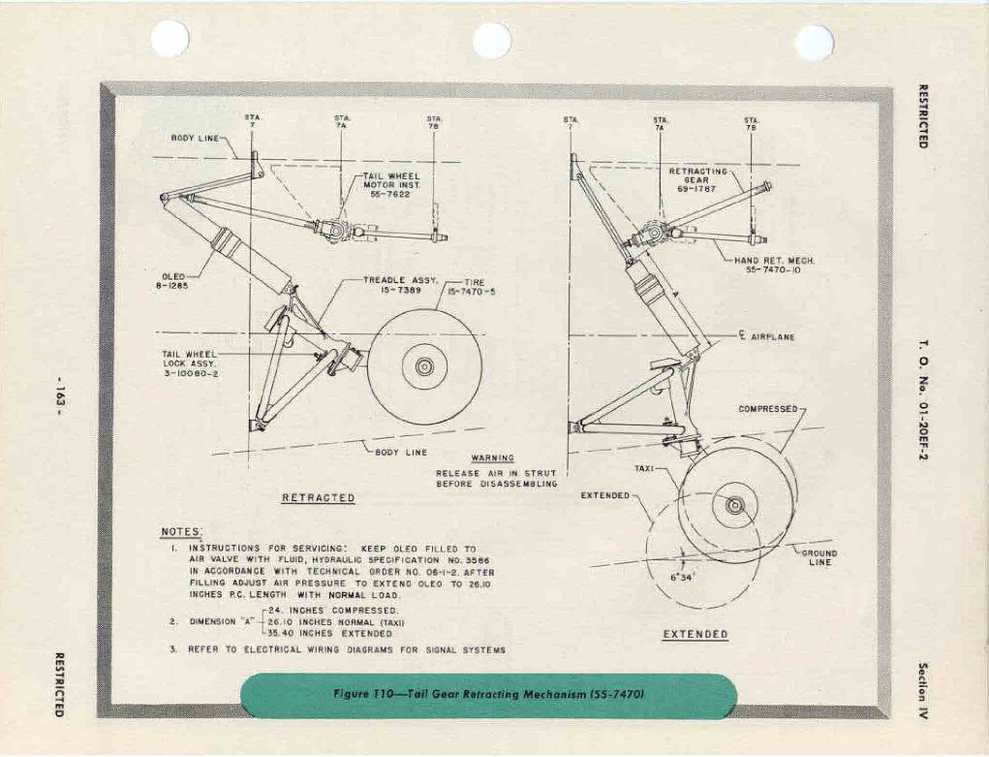

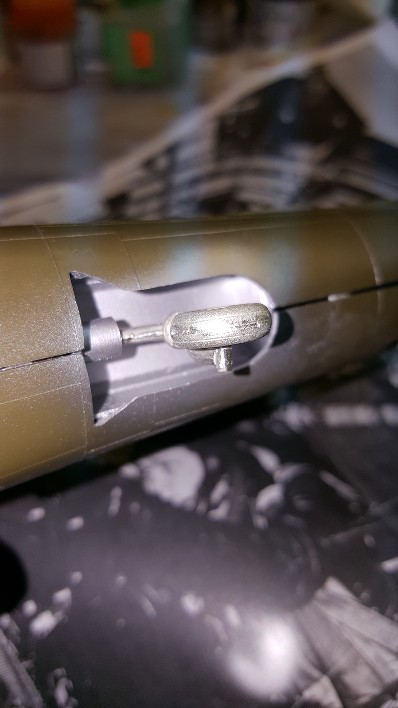

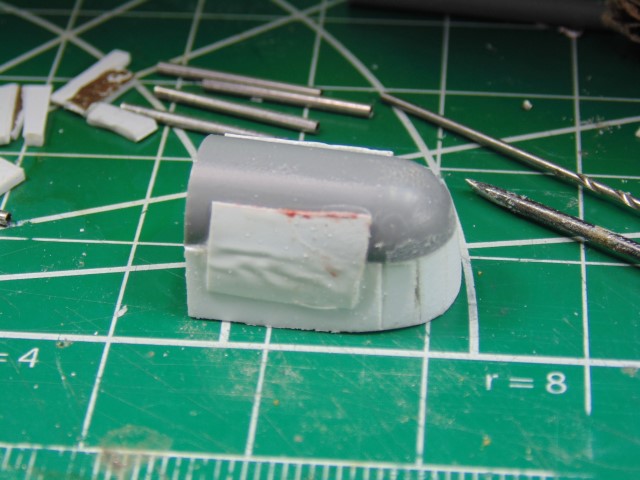

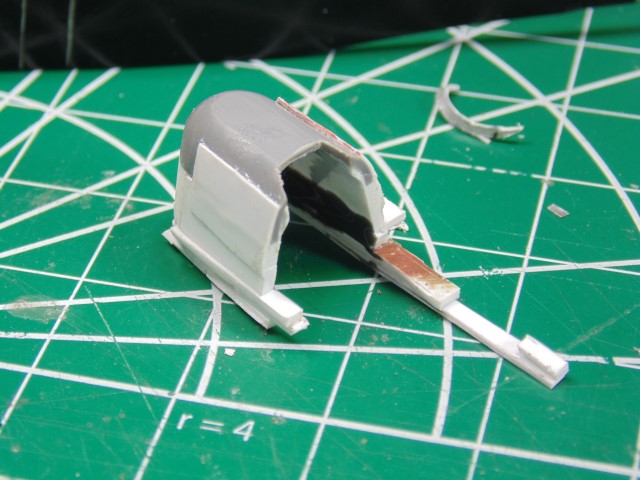

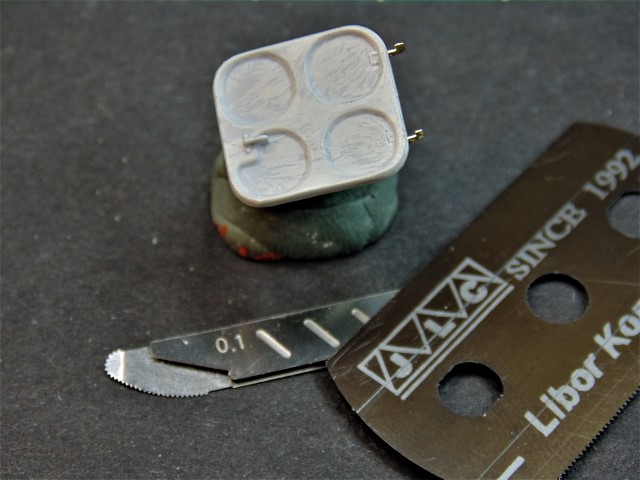

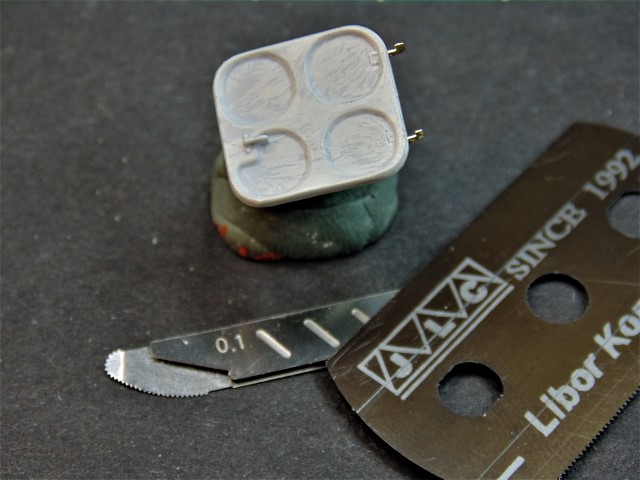

And here's the start to his re-do of the radio room roof. Before going to the pictures, here's his explanation of what you see:

Quoted Text

After taking some measurements and pouring over the drawings I set out to do panel lines. However, with the different colors from plastics, filled lines and old primer it was best to prep for re-prime and have a clean surface.

I'm happy with this. For me, the radio room roof was one of the most problematic areas of the whole build. Now I know it will have the right look.

More to follow, and I may even find time to make some small progress on one of my own projects this weekend.

I learned from my NC friend Art, who was also a former friend of the guy who abandoned the "Vicious Virgin" project on me, that the man passed away last Thursday. Despite our massive falling out, the news saddens me.

I learned from my NC friend Art, who was also a former friend of the guy who abandoned the "Vicious Virgin" project on me, that the man passed away last Thursday. Despite our massive falling out, the news saddens me.