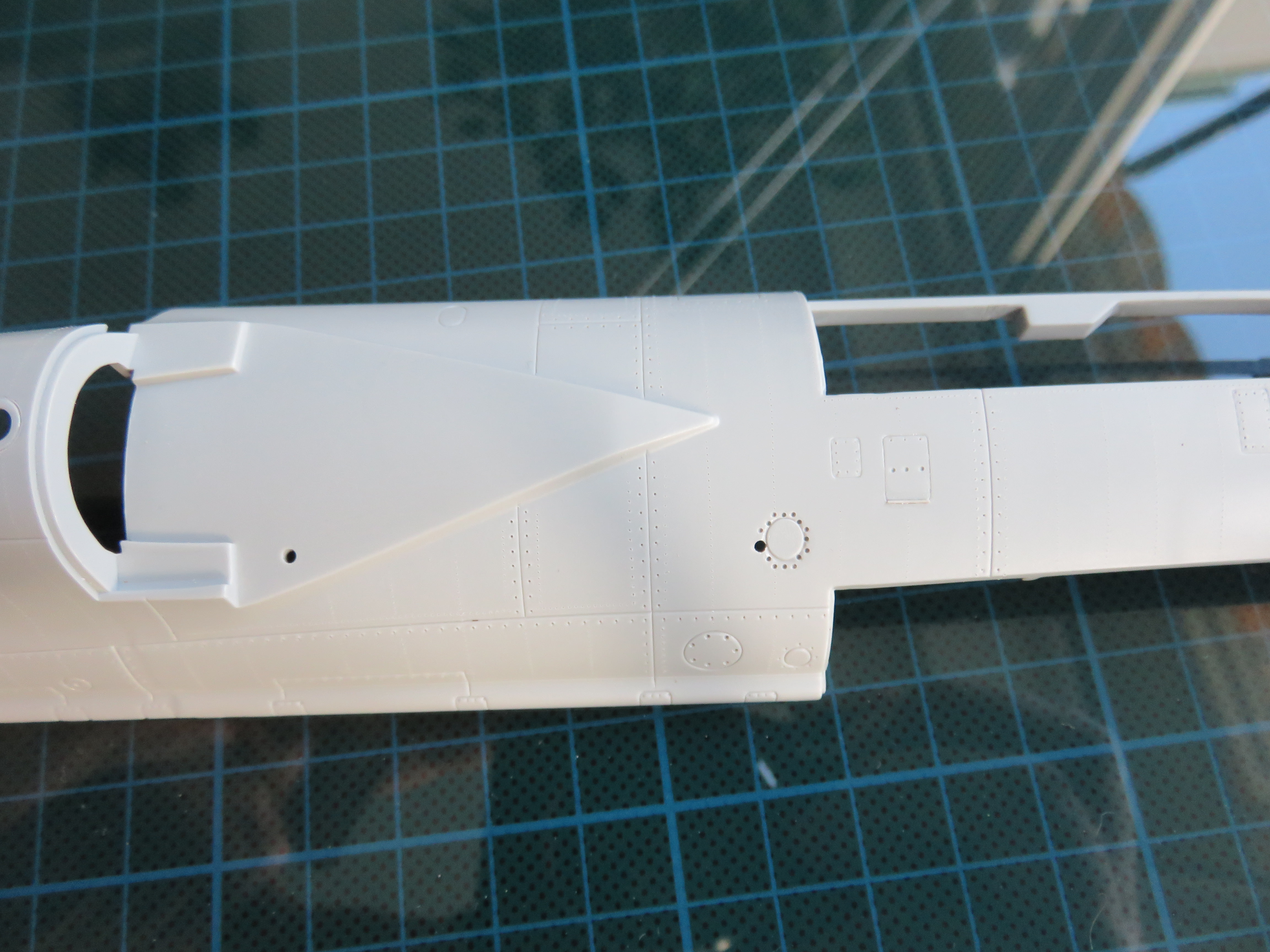

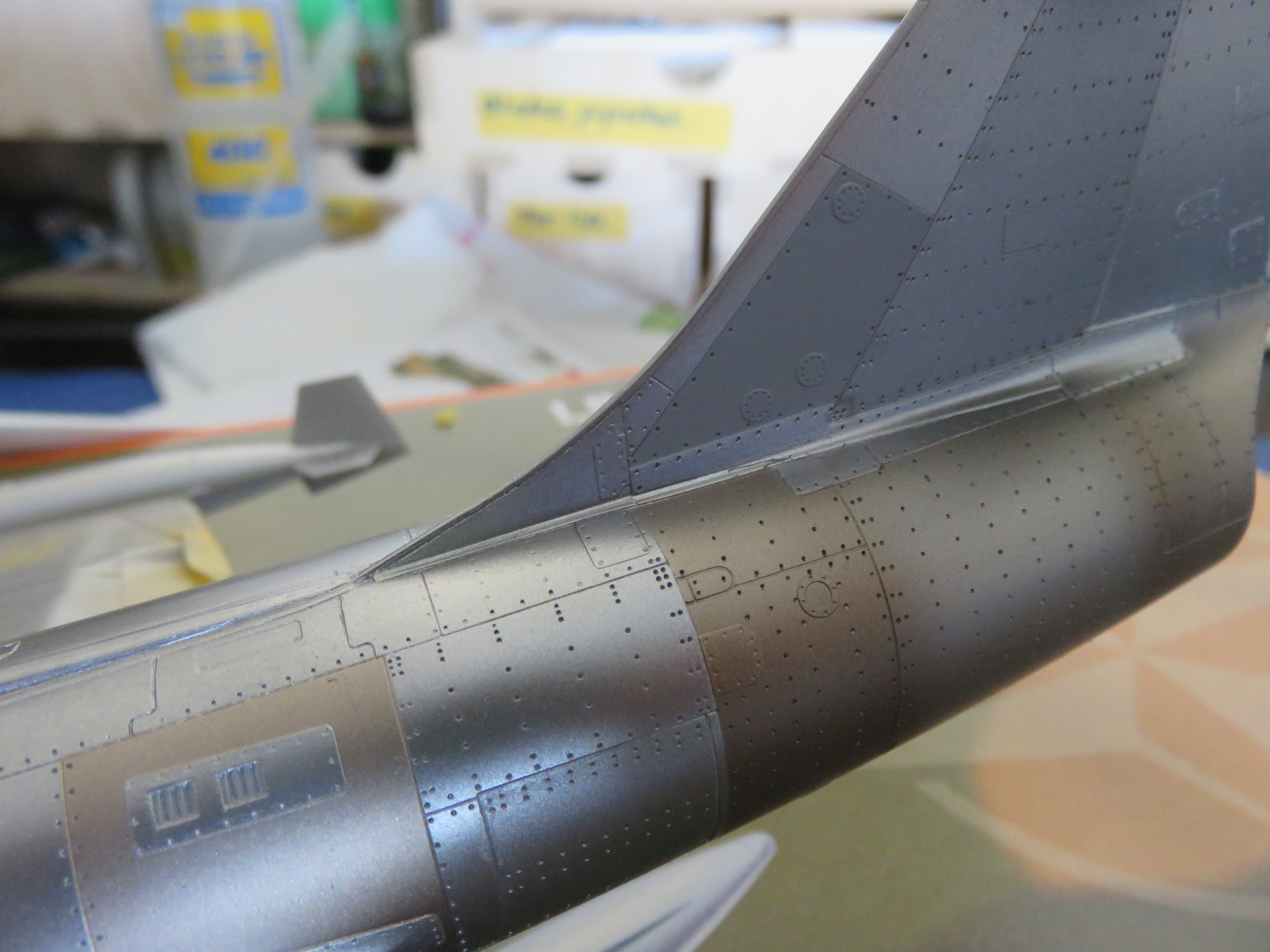

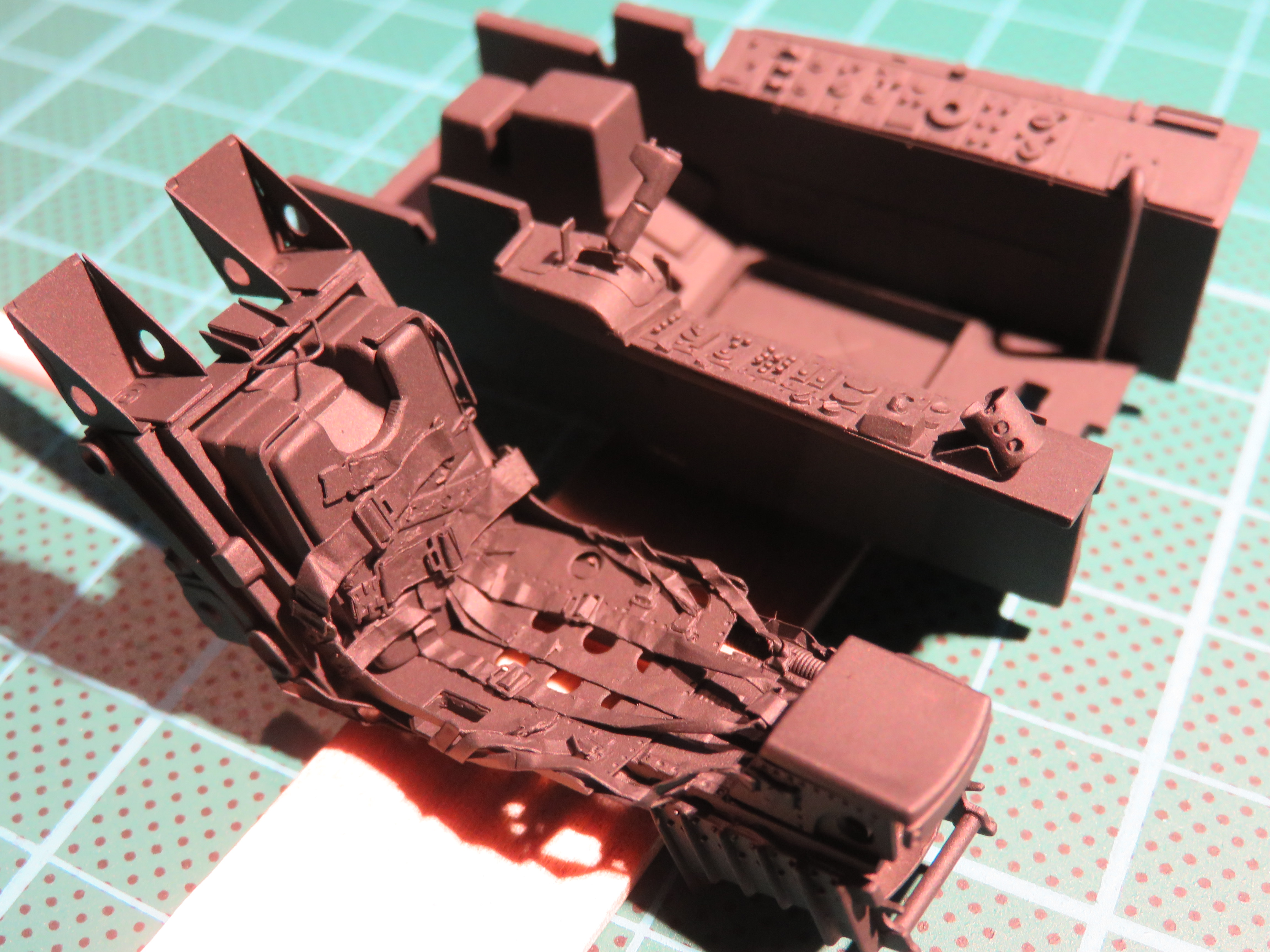

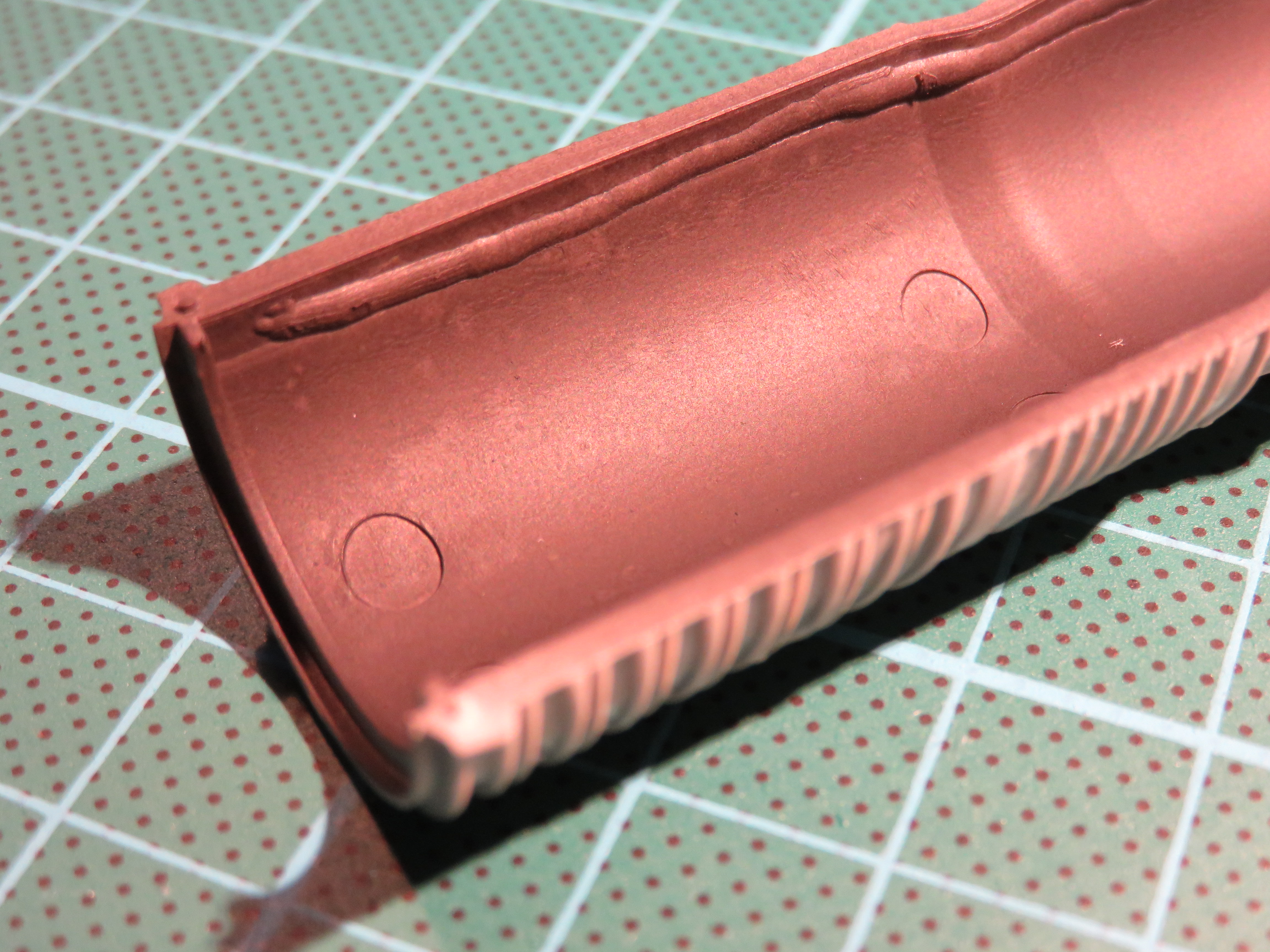

It's a bit exaggerated in this photo because I'm holding the parts together, but you can see the problem:

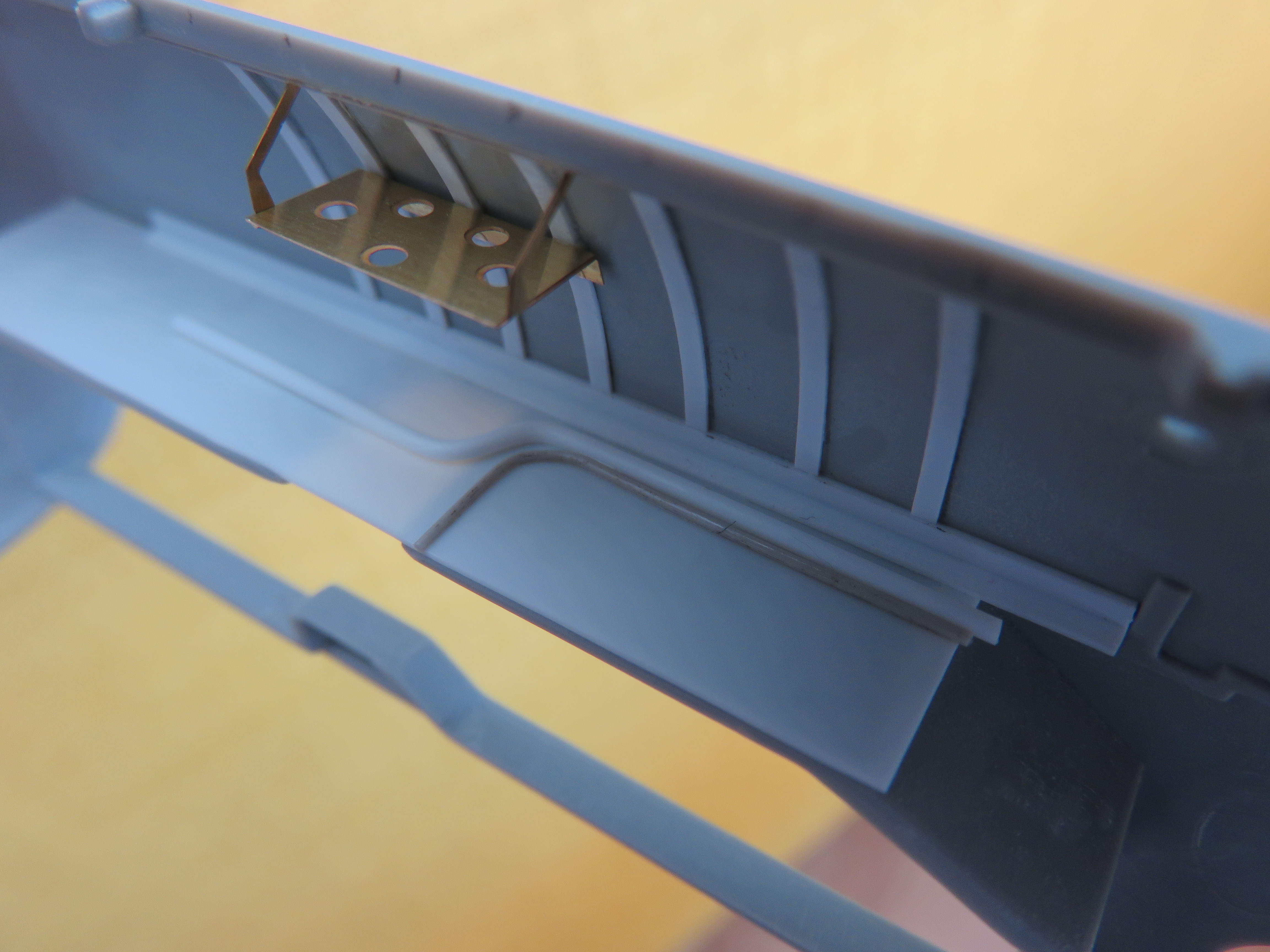

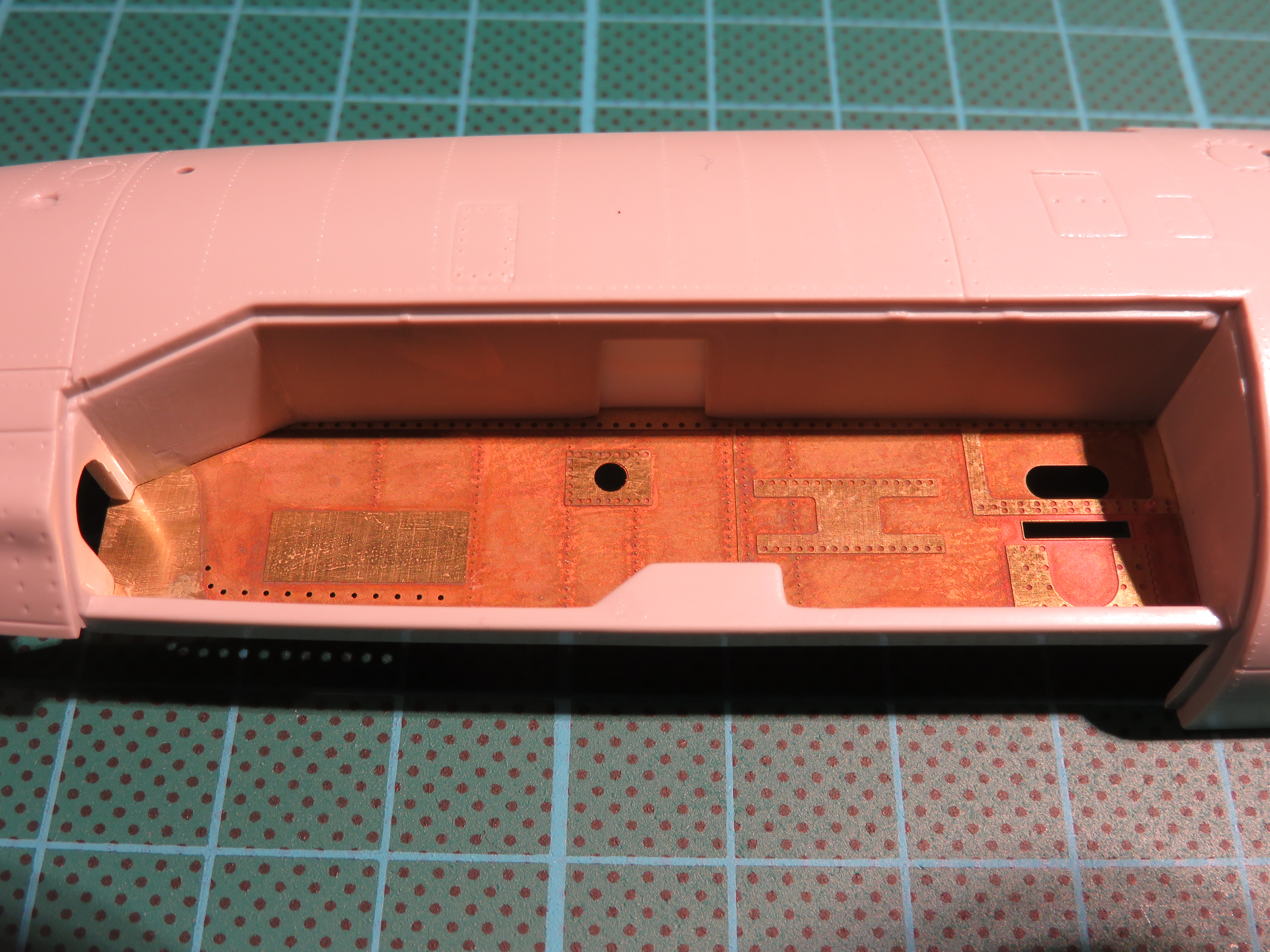

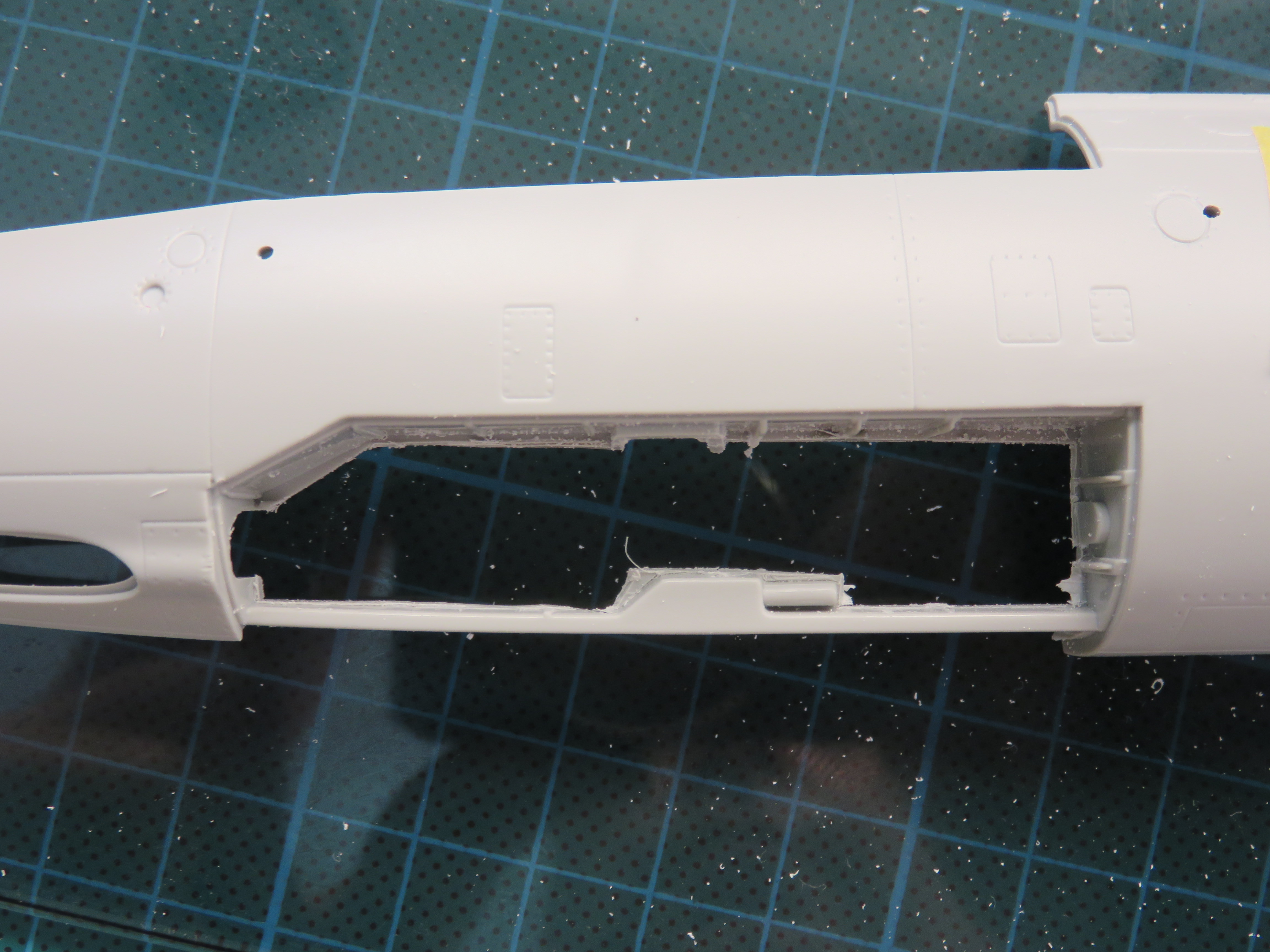

Neither the Italeri kit nor Eduard offer us anything to fill it. That left me thinking Iíd have to scratch some details, and that in turn had me checking the gun bay area because it needs a lot of modification to fit the Eduard parts and it is right next to the area of fuselage I need to work on. I didnít want to be hacking away removing chunks of plastic with delicate scratch building on the other side. One misplaced finger and details would be squashed. As a consequence of all that I made the major modifications needed to the gun bay before I started scratching the extra detail. The pictures below tell the story.

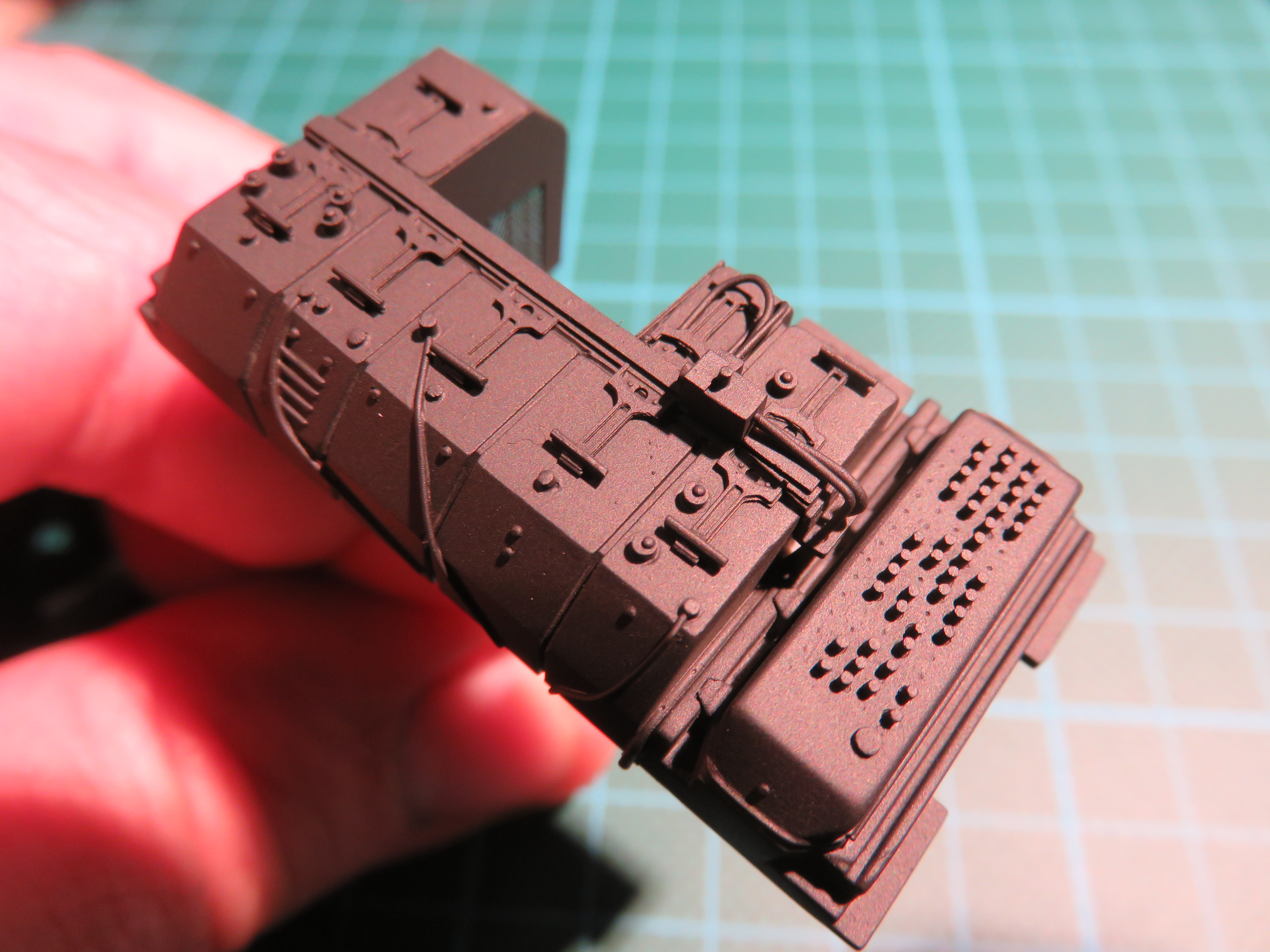

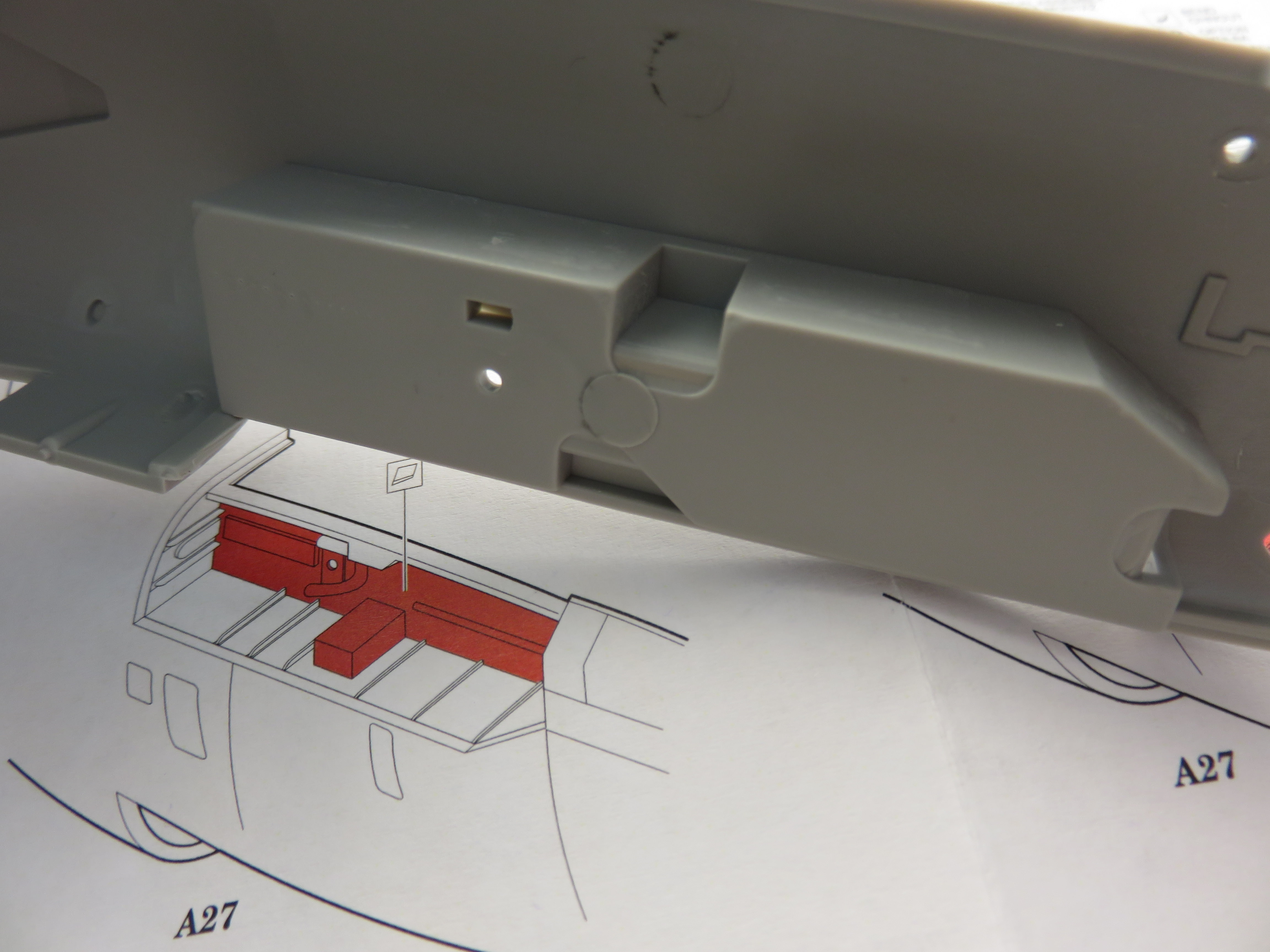

This one shows the reverse side of the gun bay - right where I need to scratch some extra interior details - and the Eduard instructions (showing the other side). Red means cut - serious surgery!

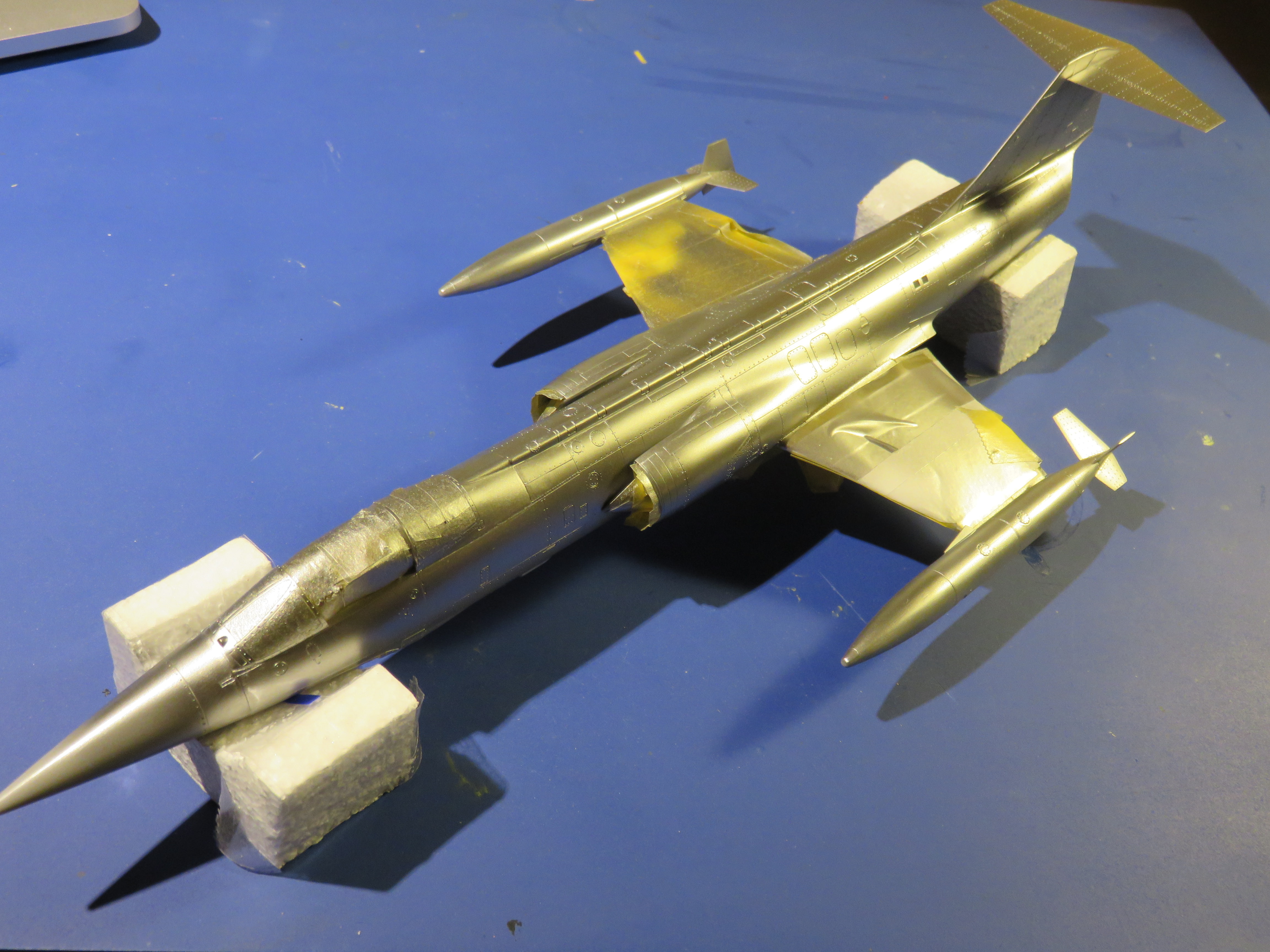

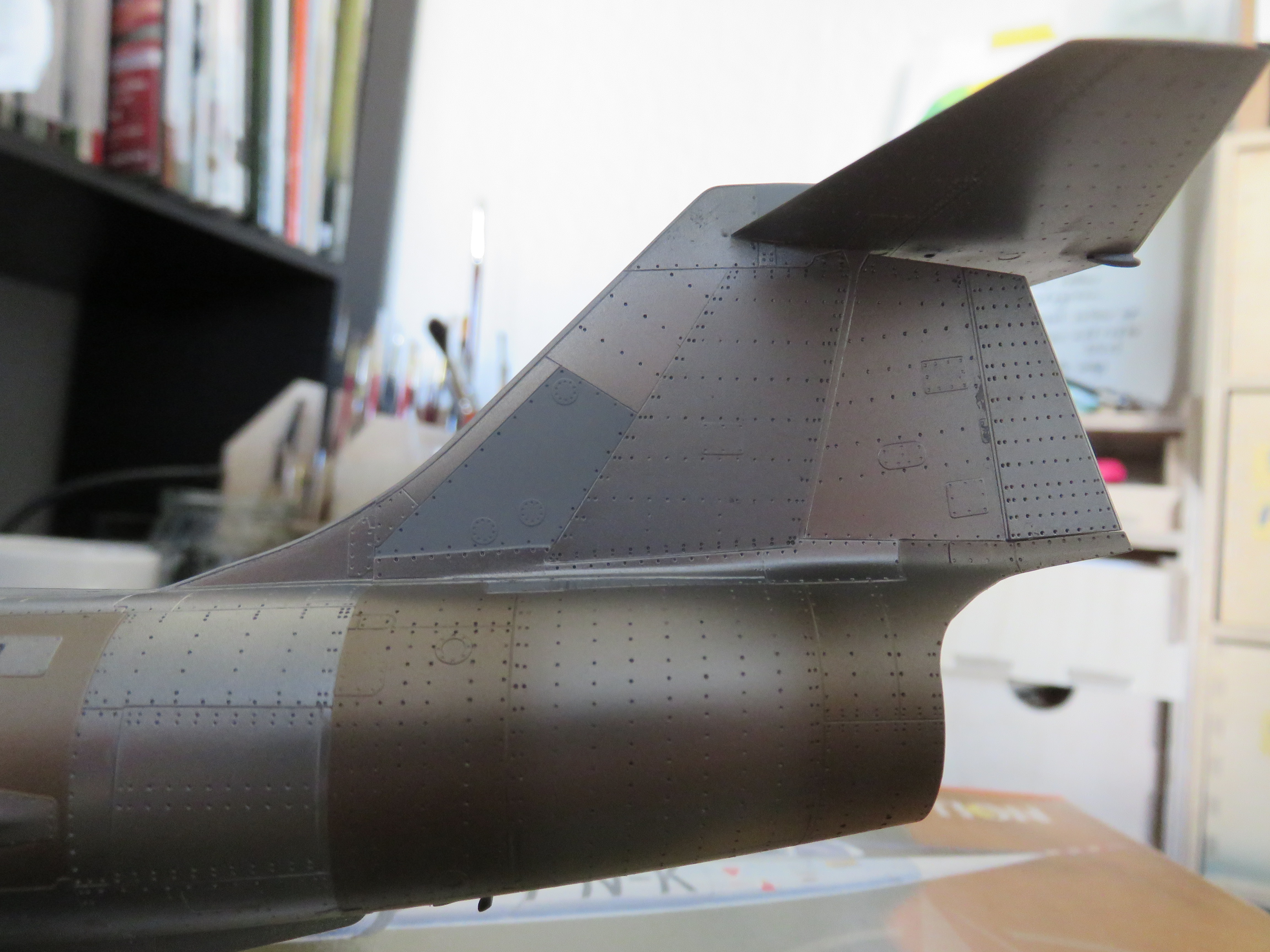

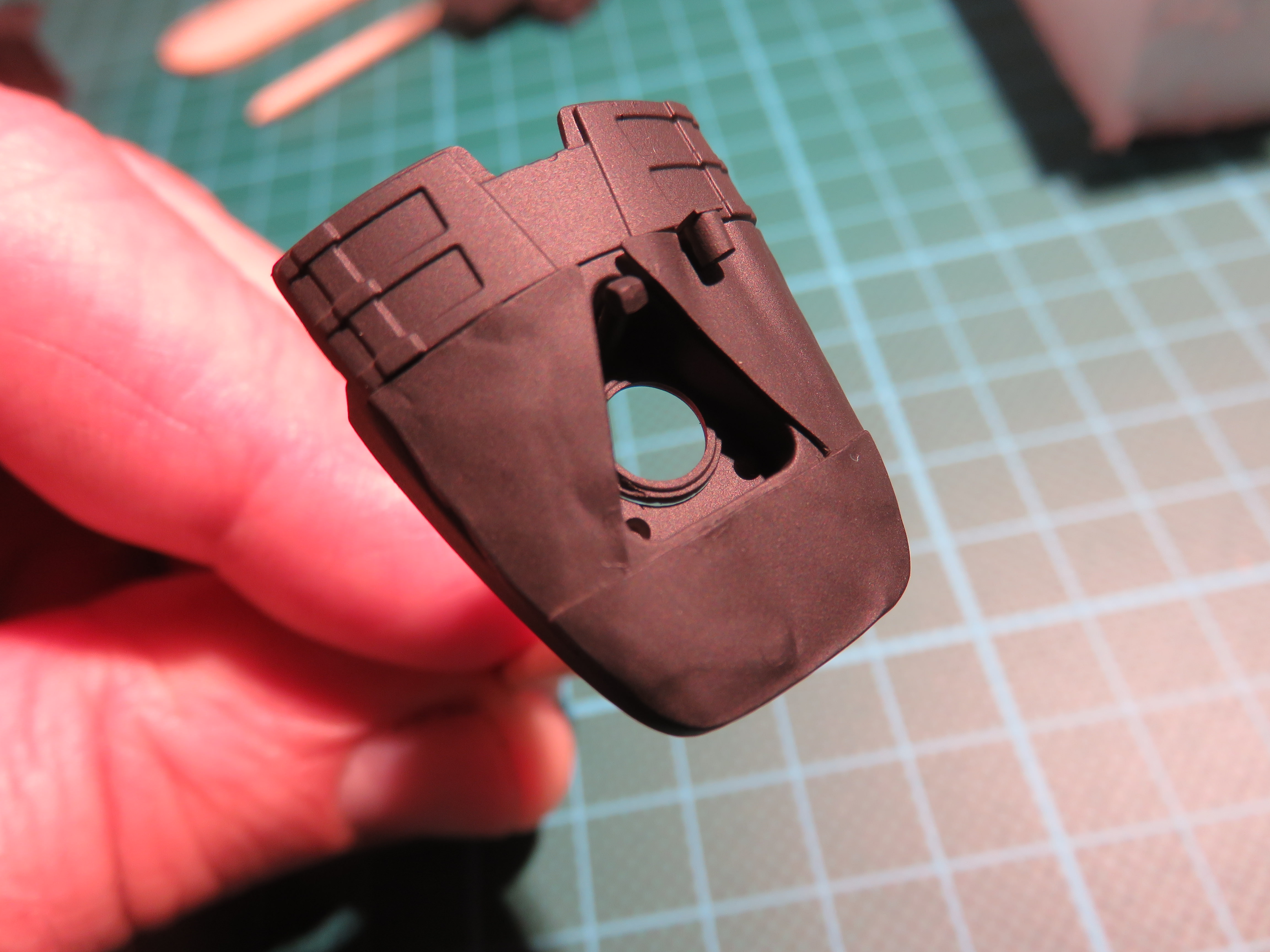

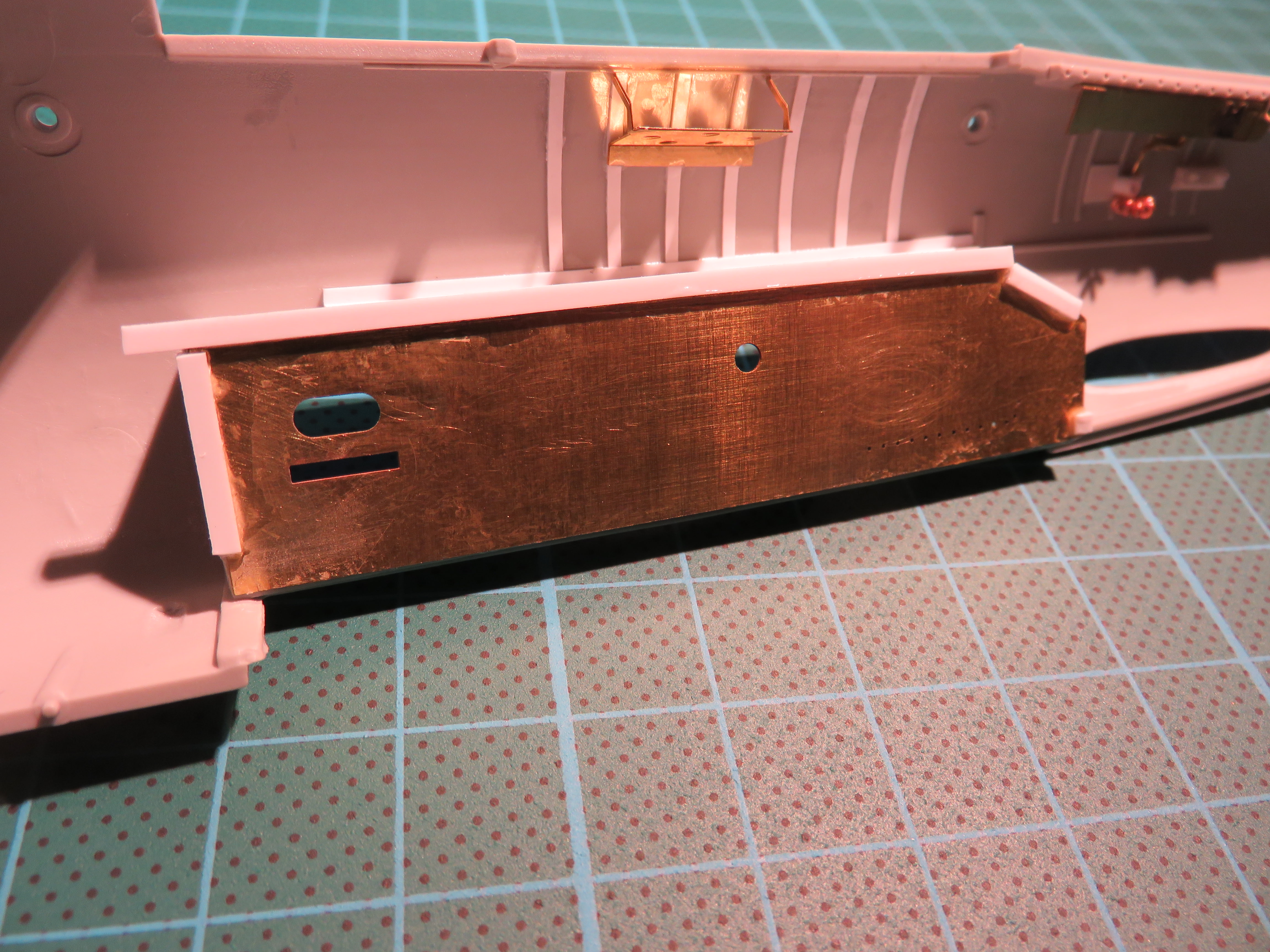

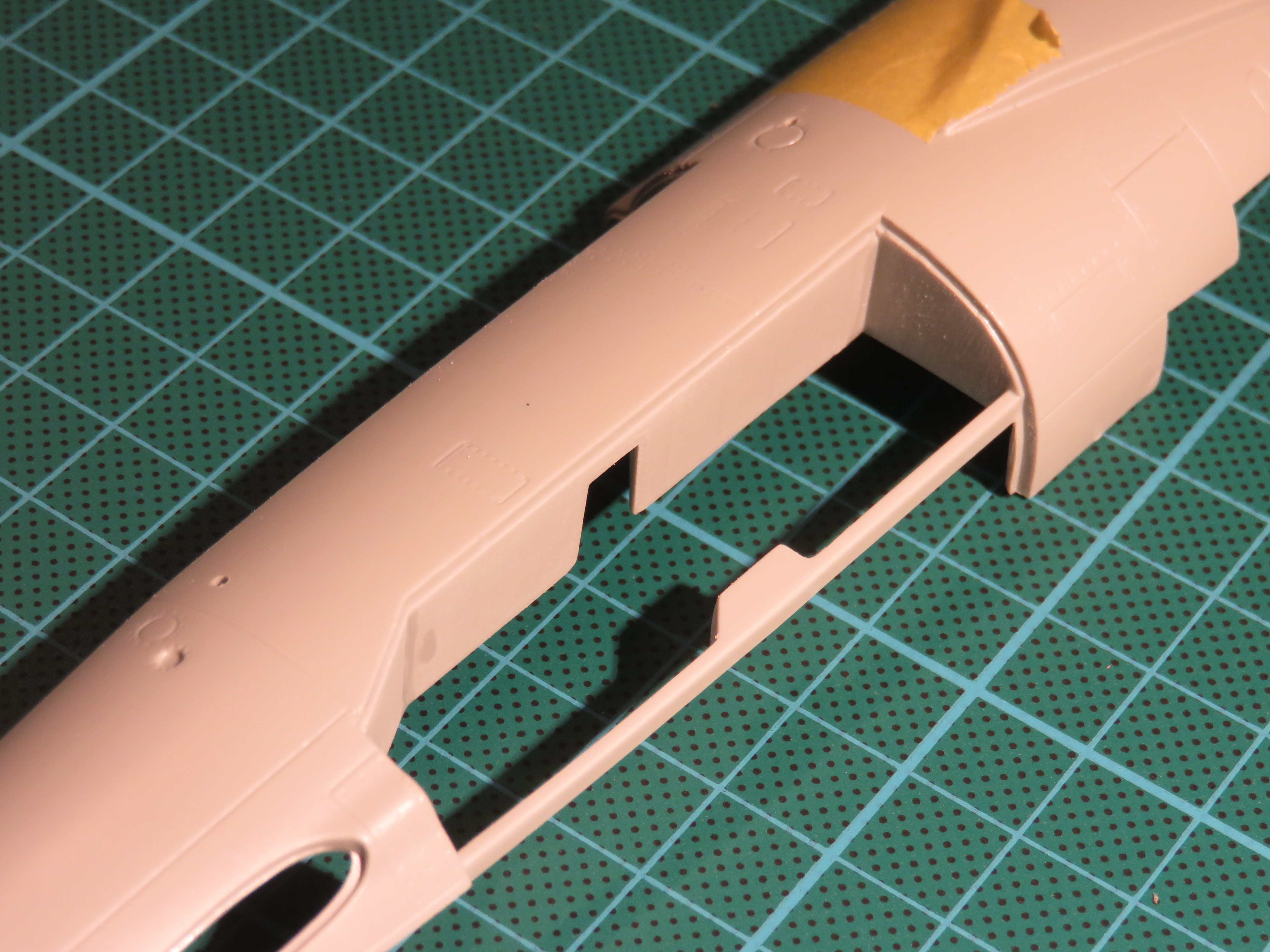

After sanding with 320 grit, 600 grit then 3000 grit sanding sticks and little bits of sanding sponge to get into the corners:

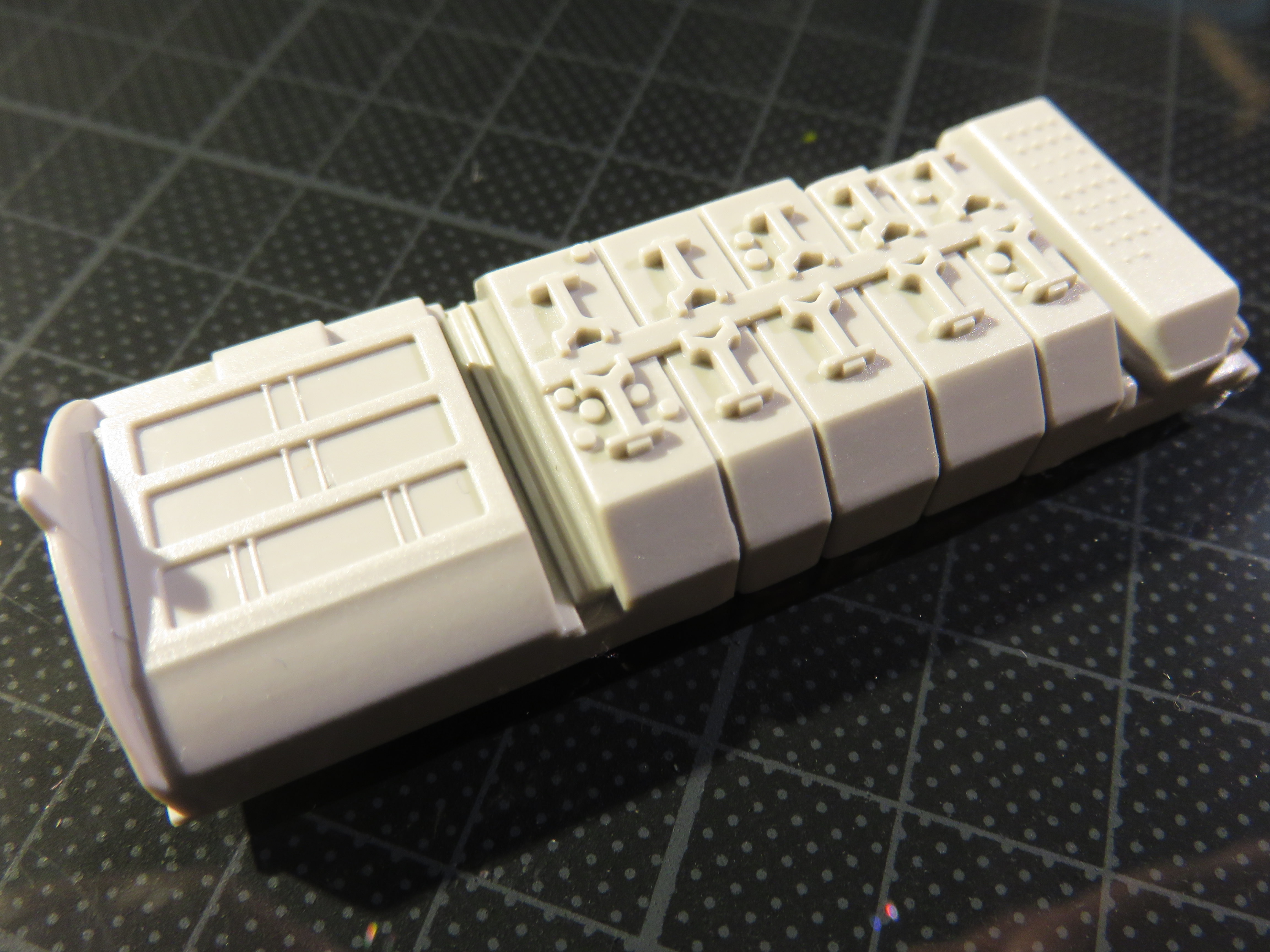

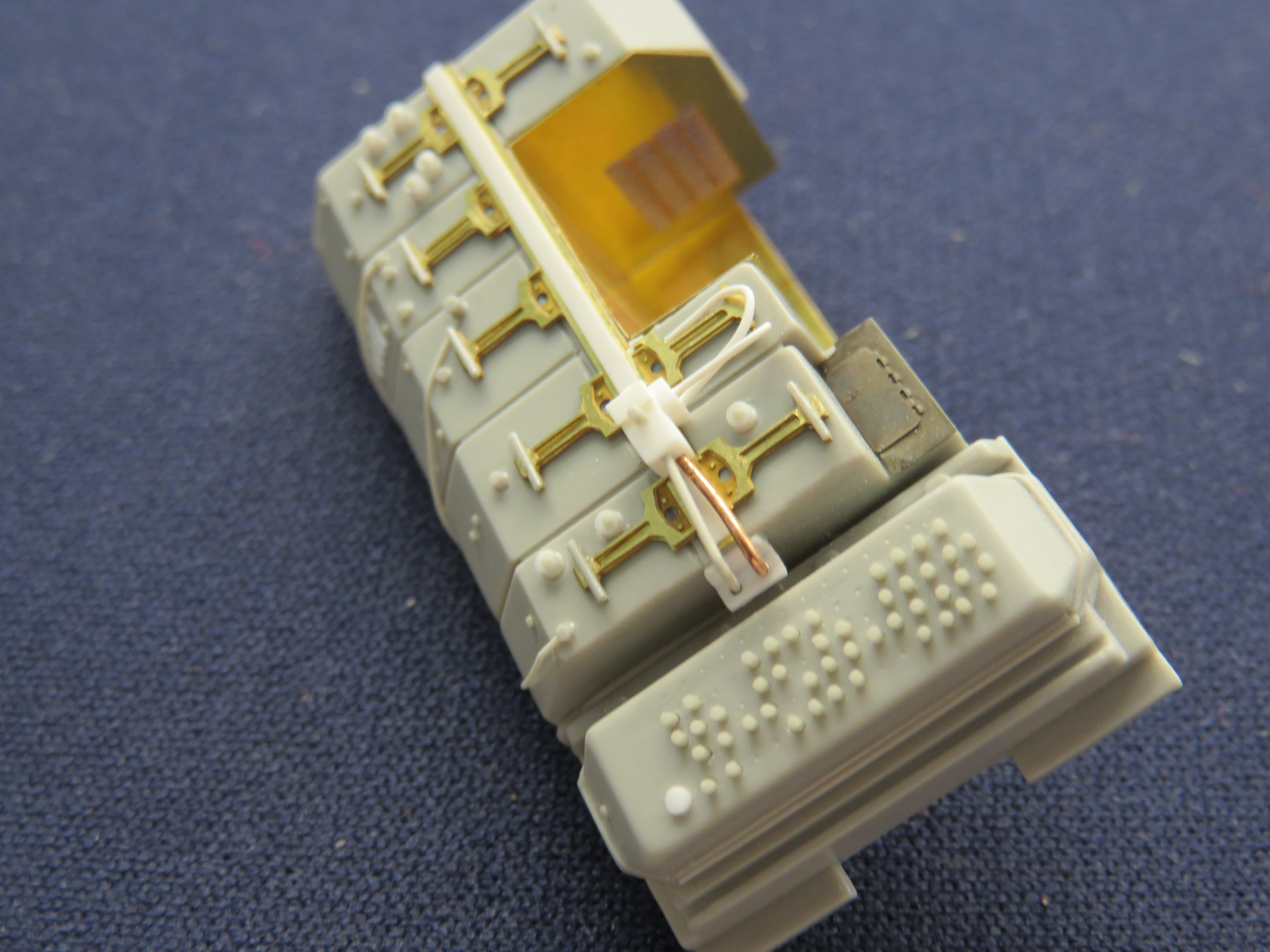

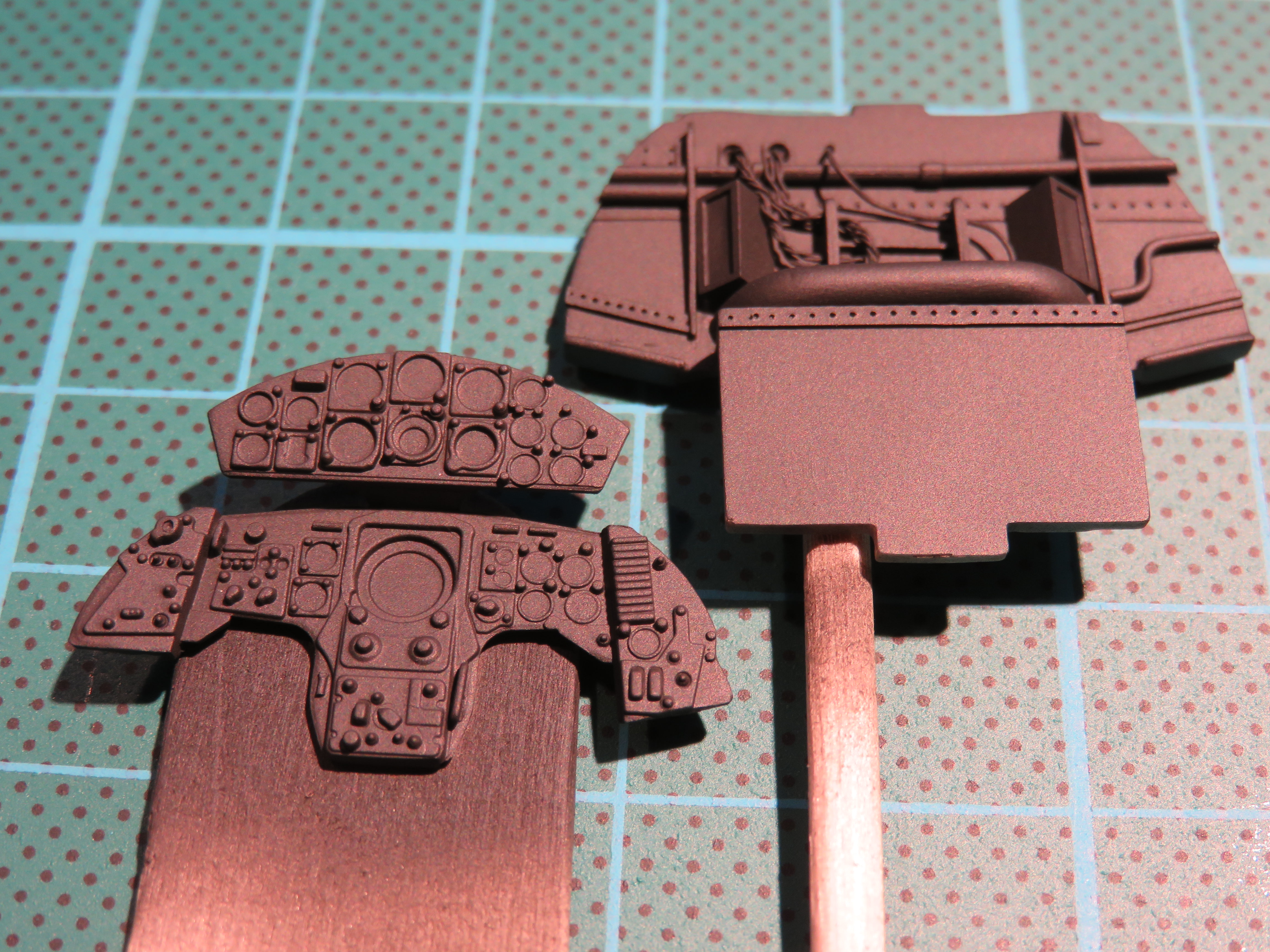

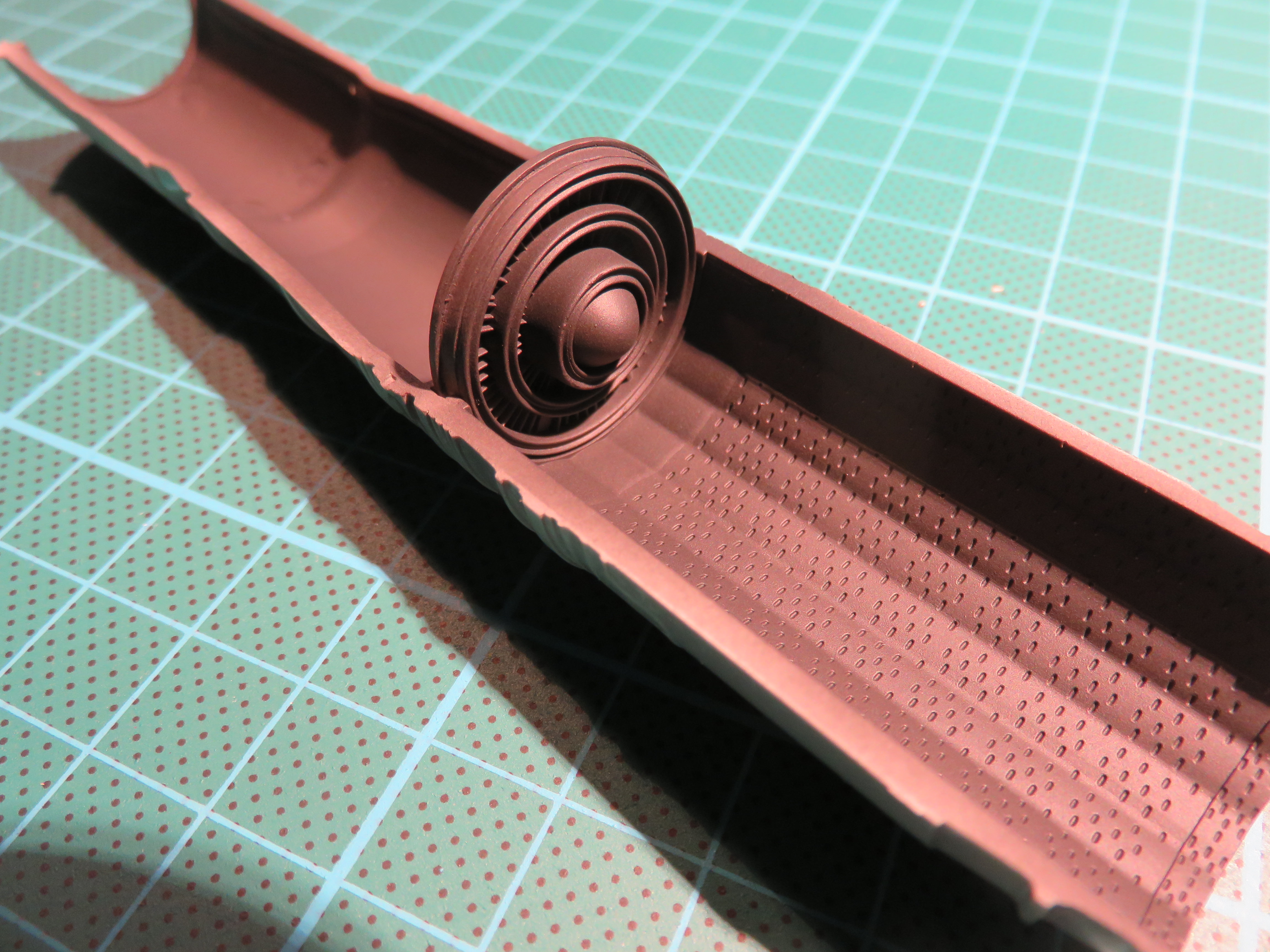

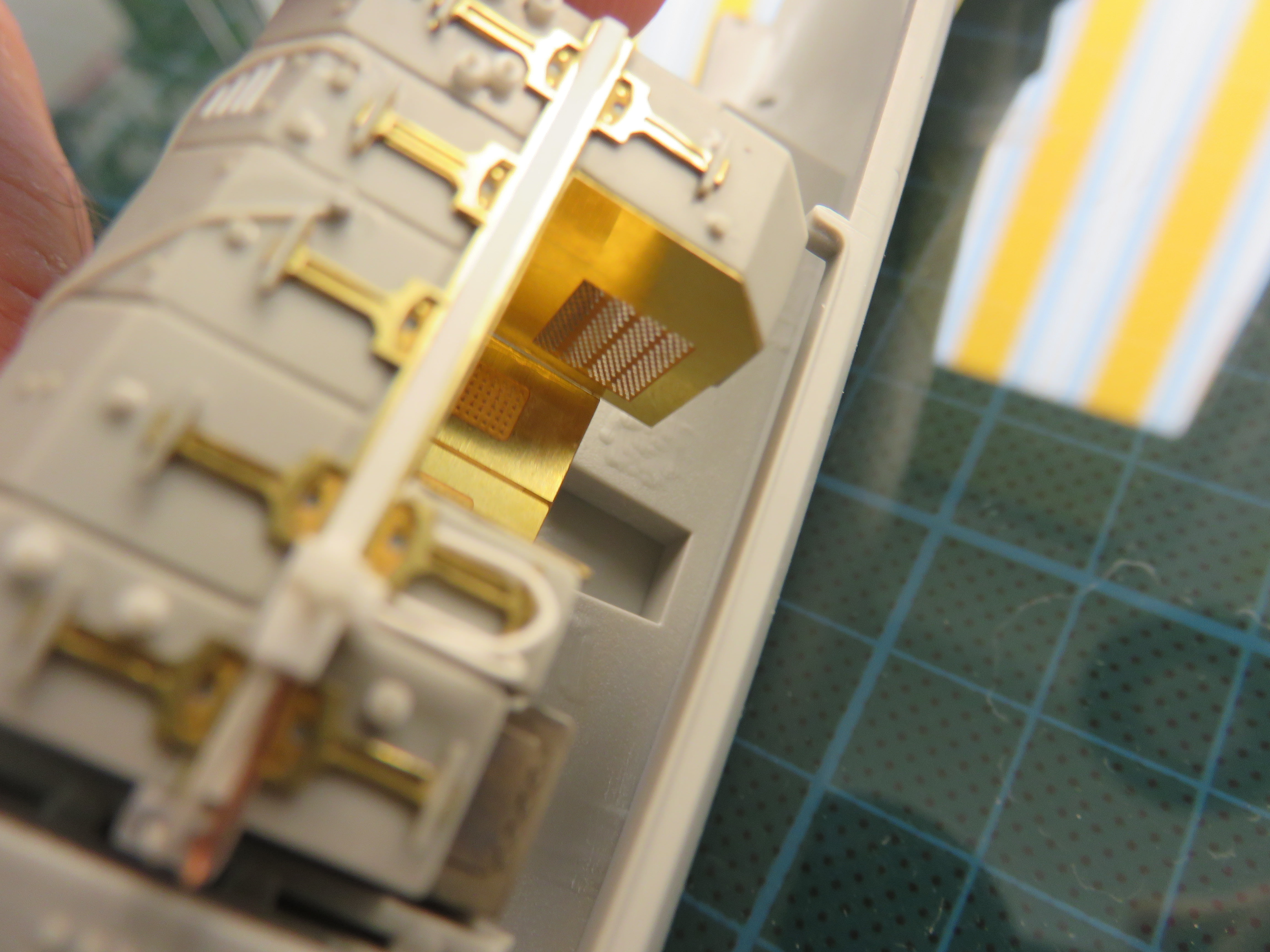

By the way, I finished off the switches on the junction box using the reverse end of my trusty rivets, supergluing them in place and then sanding them all down to the same height. That, combined with adding the last of the PE got me the finished thing. Hereís the item as it was and as it is now. It feels like it was worth the effort. Phew!