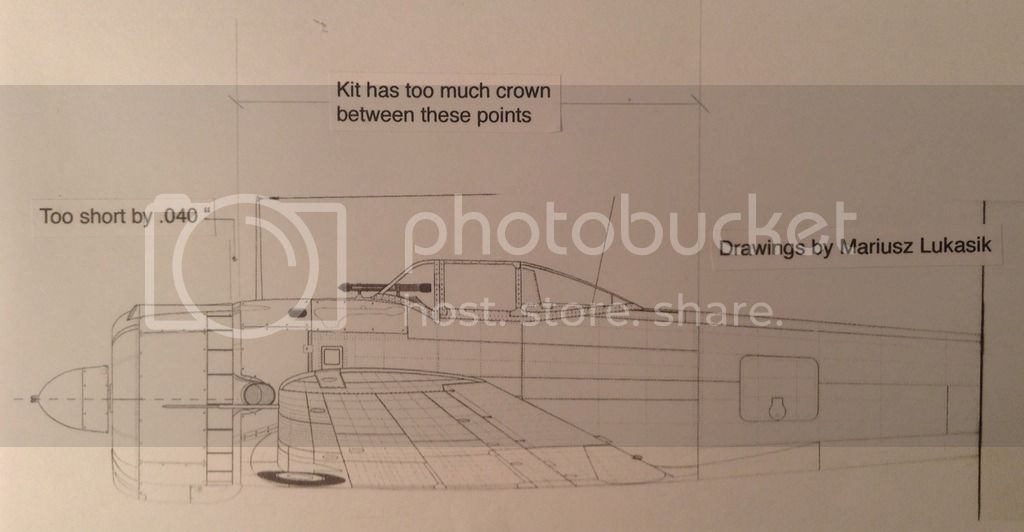

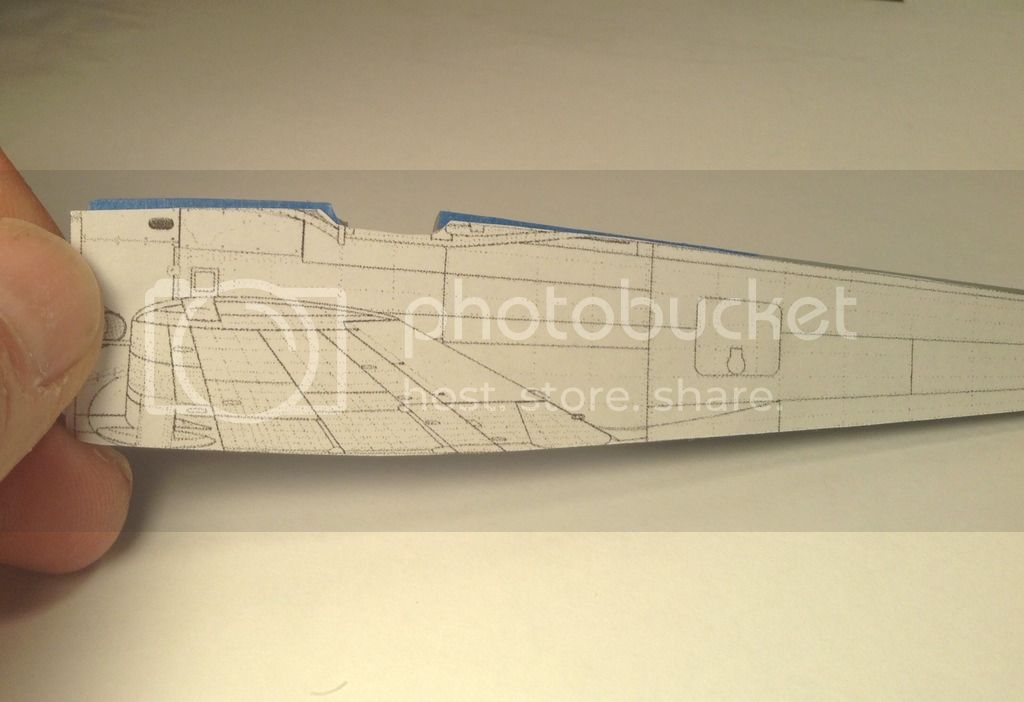

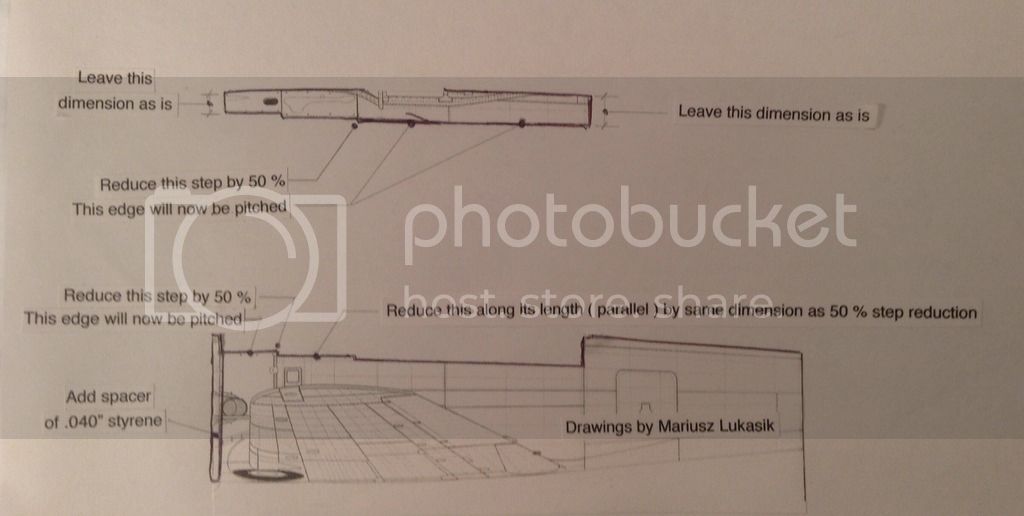

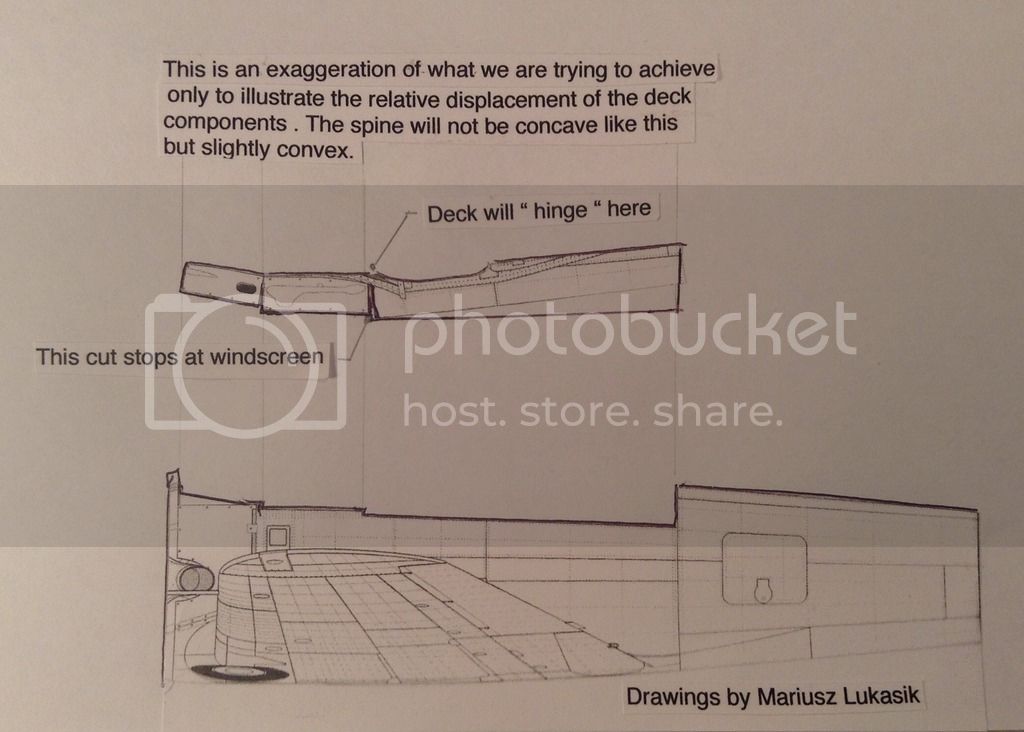

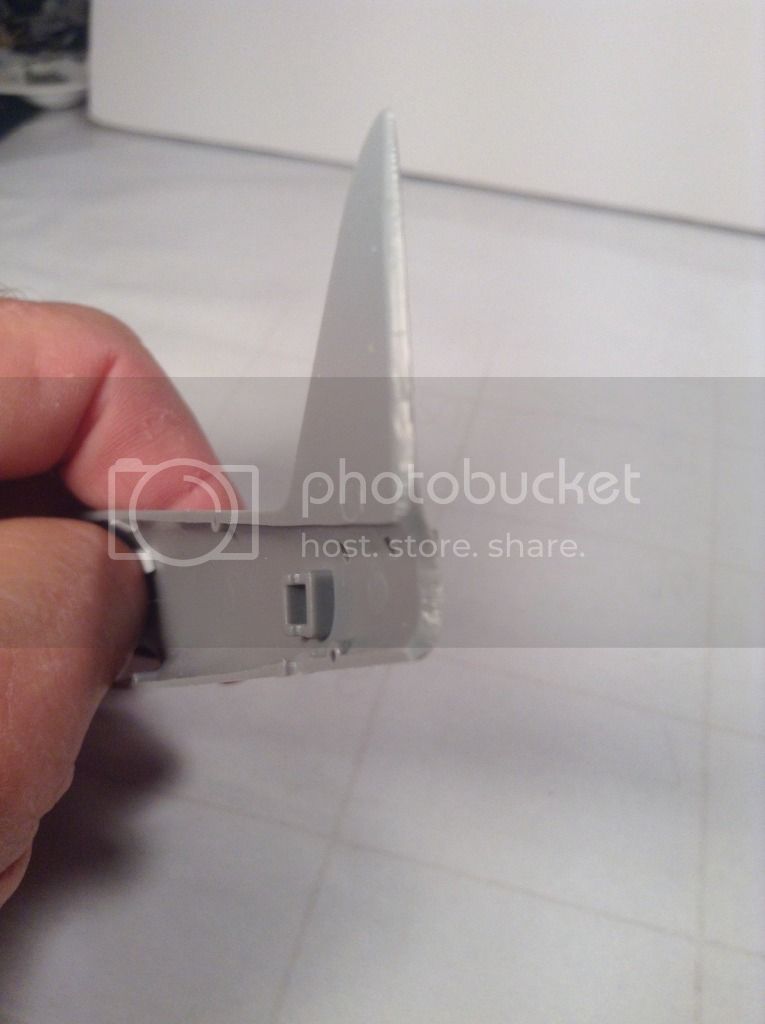

Some more progress to report but first I've discovered another shape issue to deal with. The Hasegawa cowl is cast in one piece including the cowl flaps. Likely as a concession to mold release considerations, the cowling has been made with too much pitch - especially so along the dorsal spine . This unfortunately adds to the " hogged" appearance of the fuselage . Photos and the Lukasik drawings show that the top edge of the cowling is only slightly crowned and nearly parallel to the engine / thrust centerline. This is difficult to discern and illustrate because the tubular blisters for the gun barrels obscure the top edge of the cowling at the center. Hopefully this photo of the cowl posed on the machinists' try square will give a hint of the issue.

Possible solutions I am contemplating are cutting away the front cowl ring and replacing it with one from the FineMolds kit or turning one from scratch on the lathe - either way the sides of the cowling will have to be cut along panel lines to allow the sides to spread a bit.

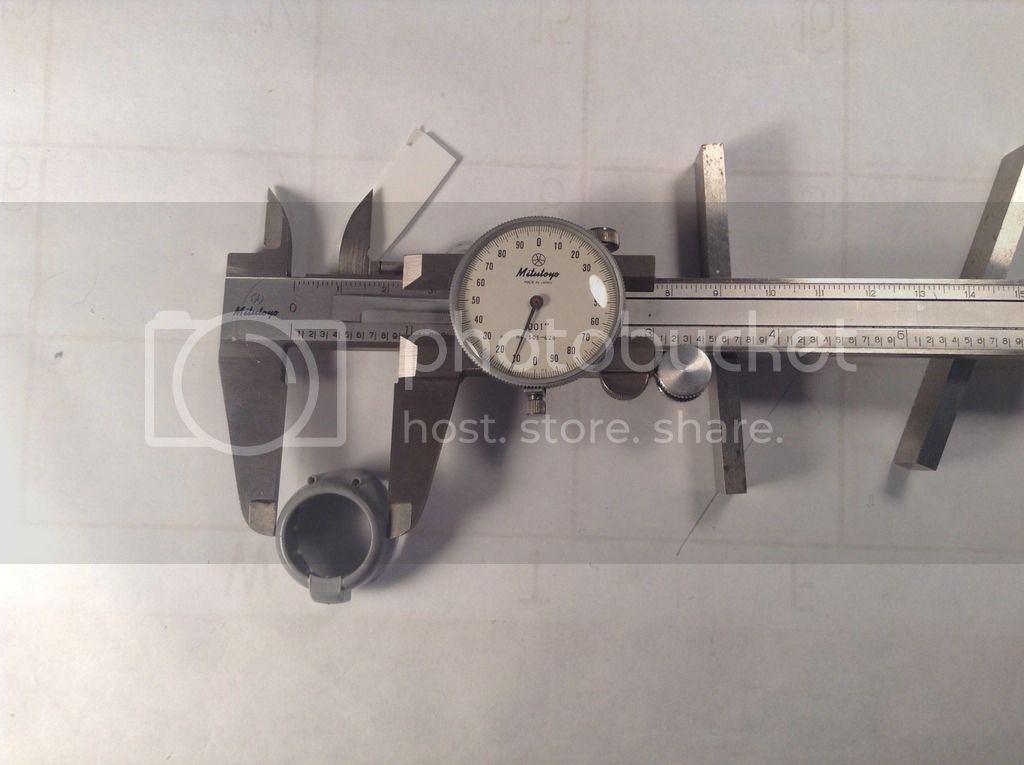

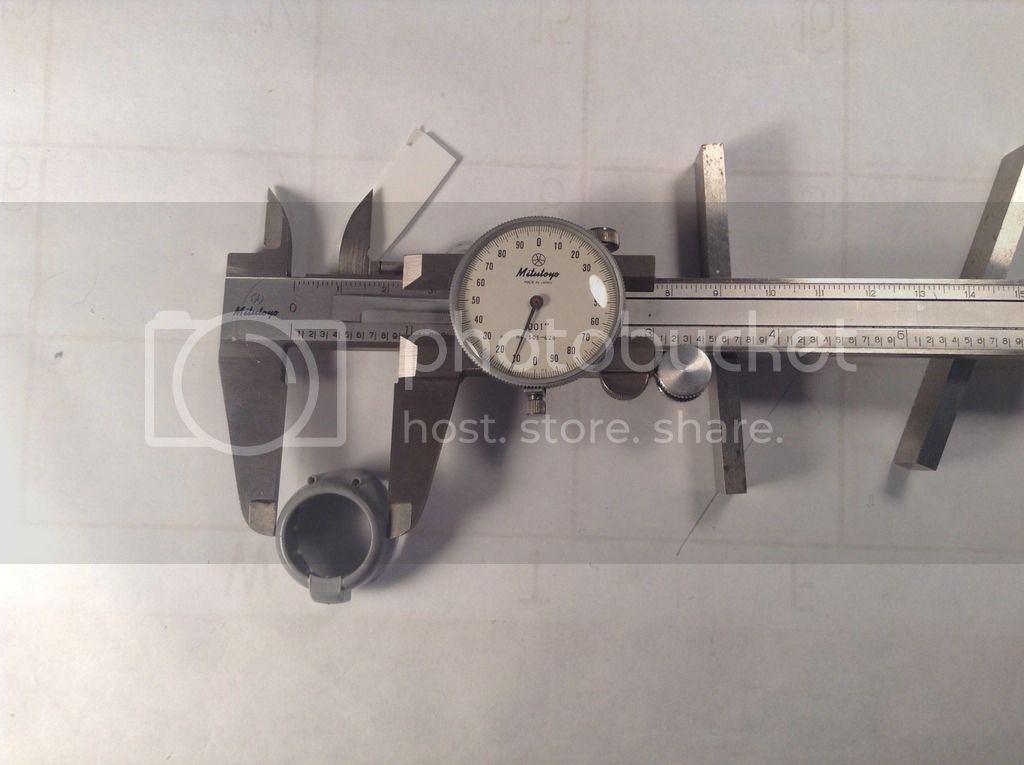

Here is the kit cowl ring diameter -

And the FineMolds diameter -

While the FineMolds ring is for the later Ki 43-II with the air inlet at the top it can be inverted with the air inlet cut away for the earlier Ki 43 - I bottom mounted unit. The larger diameter of the FineMolds unit may be enough to negate the pitch along the top edge- if it isn't then the answer may be to turn a new one from scratch.

Editorial Opinion Page

There are a few things that seem to be the subject of contention in this world of Japanese aviation - colors, accuracy of resources etc. I suppose the dearth of information on some aspects and its' attendant mystery are part of the appeal to me .This is probably a good time to reiterate my previous statement that I cannot vouch for the complete accuracy of the Lukasik drawings. I don't know to what extent they were researched - I do know they exhibit wonderful care in draftsmanship and the people involved obviously put in a great deal of work and , in keeping with the spirit of this effort , they look right to this trained eye. I'm all for accuracy and I applaud those who put in that kind of effort and I'm also grateful that resources such as this set of drawings are available. I hope this doesn't get misconstrued as a rant - only a testament of a sort- Thanks for listening !

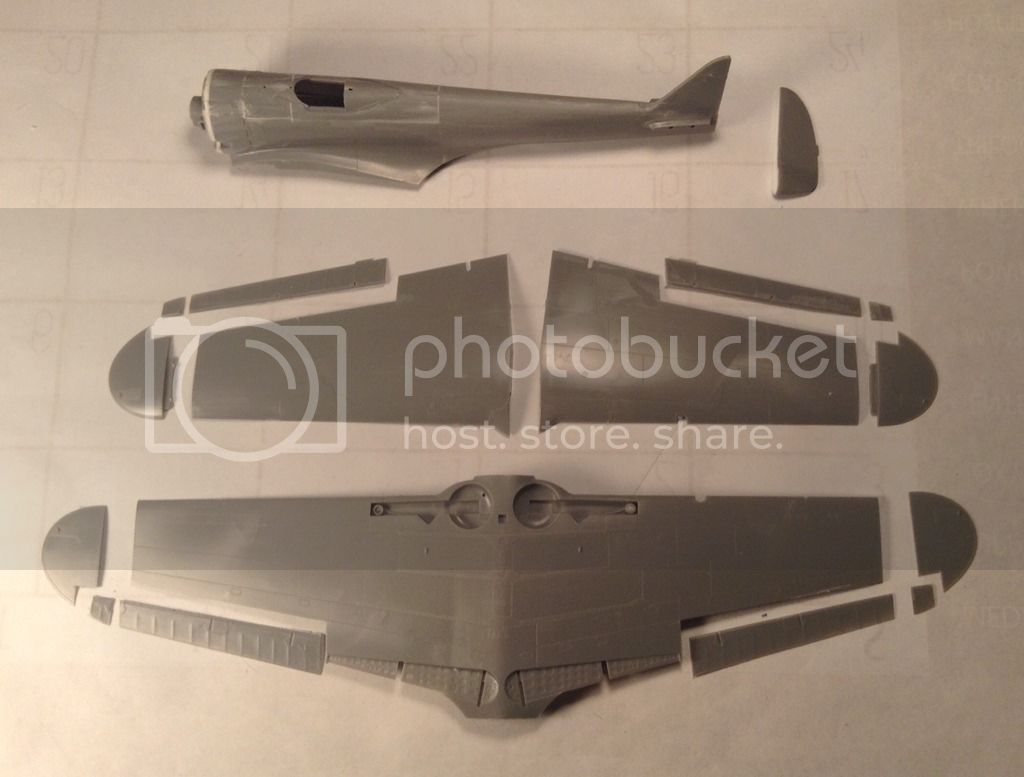

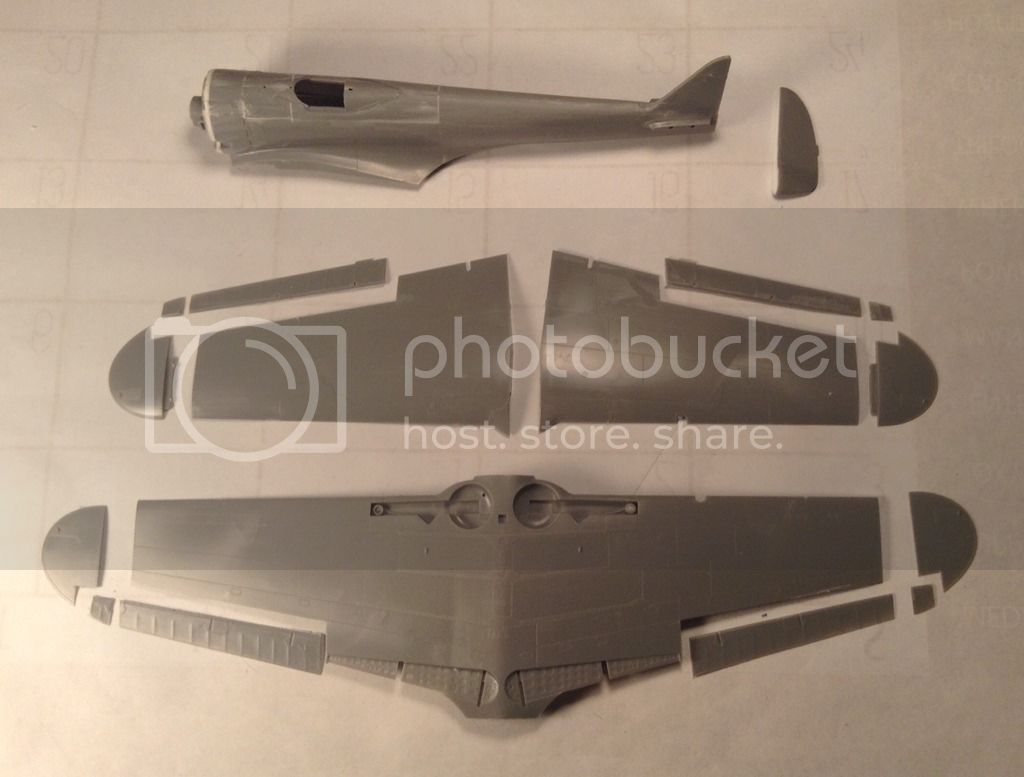

Moving on to the wing- the control surfaces have been cut away-

and the wing assembled and elevators cut away-

Next task will be the cowling issues.

Thanks for looking in-

Cheers and Happy Thanksgiving Day to all ! Richard