OFFICIAL: Flying Boats Campaign

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Wednesday, May 24, 2017 - 07:48 AM UTC

Quoted Text

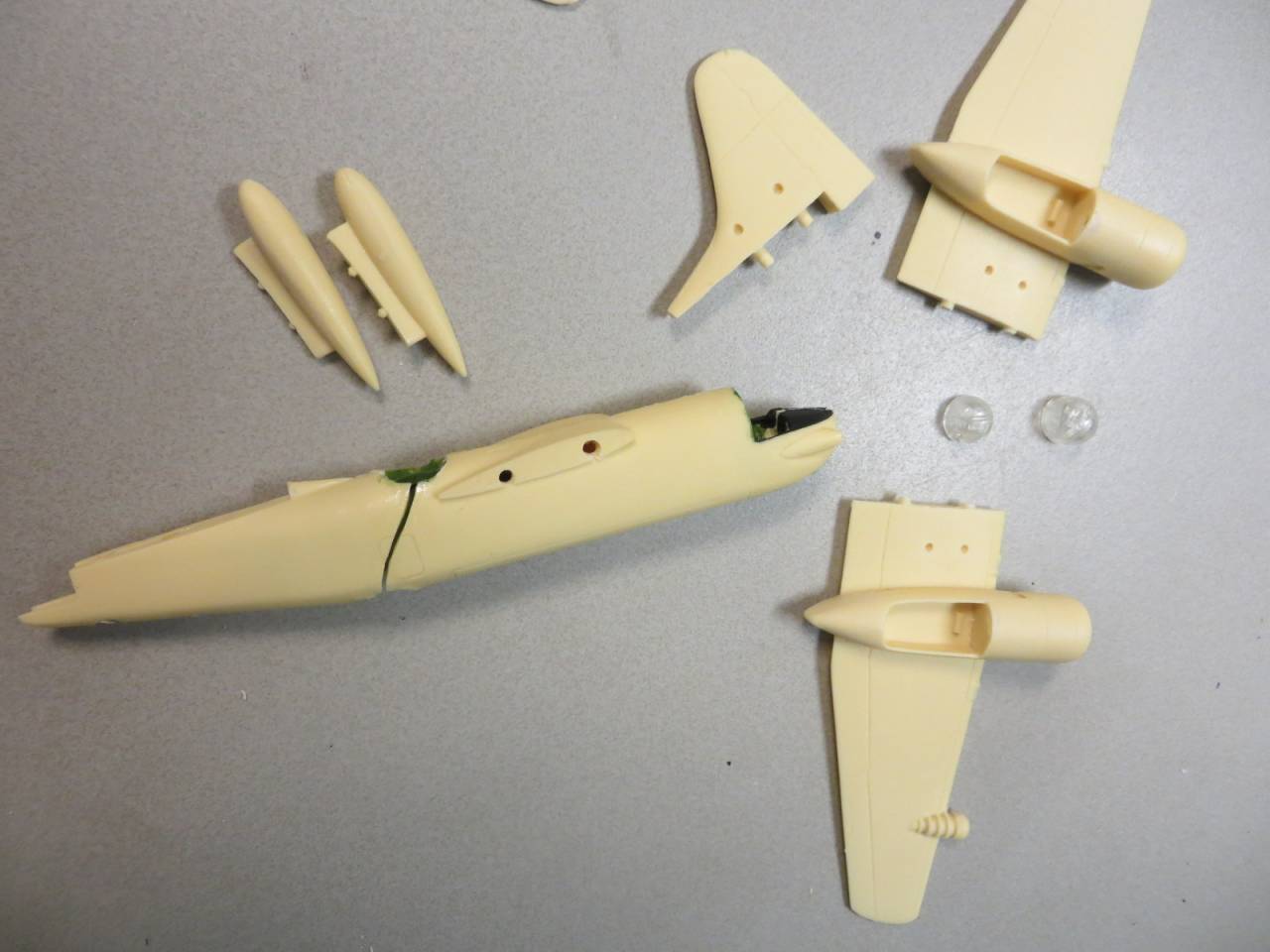

This mixed medium kit is going to drive me crazy. Trying to fit the resin fuselage together with the interior is almost impossible.  Maybe I should send it to you Jonathan

Maybe I should send it to you Jonathan

Bob

Bob-- that's what Aeroscale is all about-- if you have a problem, ask, and I'm sure you'll get all kinds of help. I for one am looking forward to these builds.

VR, Russ

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Wednesday, May 24, 2017 - 08:34 PM UTC

If it aint broke dont fix it.

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Wednesday, May 24, 2017 - 11:32 PM UTC

Quoted Text

Russ, I appreciate the help I may send you the resin parts so they don't cause me to pull the rest of my hair out LOL. I was just kidding with Jonothan

]

Don't pull out your hair-- I built CMRs big seaplane for Internet Modeler a few years ago-- I have a few gray hairs from that build, but didn't lose any hair. This looks like an interesting kit, and I'm looking forward to your rendition of it. Don't send it to me though-- I have enough on my bench to last me the rest of my lifespan--including Delta 2's S-55X, I don't want to shorten my life anymore than it is!

VR, Russ

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Thursday, May 25, 2017 - 01:14 AM UTC

Russ, I would love to see your S-55X in progress and finished. BTW I only have 3 hairs

plus this SR fuse will need to be glued in sections with some heavy duty clamps.

Bob

If it aint broke dont fix it.

#259

Massachusetts, United States

Joined: October 23, 2011

KitMaker: 2,265 posts

AeroScale: 1,715 posts

Posted: Thursday, May 25, 2017 - 02:38 AM UTC

a word of caution applying clamps. resin is brittle and not ductile - does not like to bend into shape. you dont want to have to repair a crack, on top of making up an ill-fitting join.

lesson learned the hard way

If you must bend something, it must be heated in boiling water before attempting. That method is risky though as you may unleash stress in some other unexpected direction!

Alternately, aggressive use of the rasp is perfectly normal to make a fit. the other side of the coin is filling gaping gaps with sculpting putty. both of these tasks are part and parcel of resin kit building.

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Thursday, May 25, 2017 - 06:33 AM UTC

Quoted Text

Russ, I would love to see your S-55X in progress and finished. BTW I only have 3 hairs  plus this SR fuse will need to be glued in sections with some heavy duty clamps.

plus this SR fuse will need to be glued in sections with some heavy duty clamps.

Bob

Bob,

I'll send you a PM with my email, send me one back and I'll email you some shots of the S55X-- as a true Luddite, I still have not mastered this photobucket stuff yet. Here's a link to the CMR Short S-23 I built a few years ago if you are interested:

http://www.internetmodeler.com/scalemodels/aviation/Czechmaster_Resin_1_72_Short_S-23.php VR, Russ

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Thursday, May 25, 2017 - 07:09 AM UTC

Russ, all I can say is WOW! That is a beautiful flying boat.

Bob

If it aint broke dont fix it.

Nordrhein-Westfalen, Germany

Joined: March 22, 2015

KitMaker: 671 posts

AeroScale: 614 posts

Posted: Friday, May 26, 2017 - 03:19 AM UTC

Quoted Text

Russ, all I can say is WOW! That is a beautiful flying boat.

Bob

Yes Russ, great winged ship and nicely modelled!

Bob: Very nice kick off!

My Dornier Wal is just glued together but the HUMA plastic is really awful to grind and sand. It seems to be very soft, hence there alway is some burr. Is there a cure for this problem?

Oliver

On the desk: Probably a Panzer III.

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Friday, May 26, 2017 - 04:31 AM UTC

Oliver, at least the plastic will glue together better than this resin

.

Thanks for the kind comments. I will be looking for the Wal, I had thought about that kit at one time.

Bob

If it aint broke dont fix it.

#305

Christchurch, New Zealand

Joined: February 01, 2006

KitMaker: 1,673 posts

AeroScale: 1,517 posts

Posted: Friday, May 26, 2017 - 03:22 PM UTC

Hi Oliver I usually paint Tamiya thin cement over the rough areas as it'll dissolve the raised areas and make everything uniform. It won't cure any deep scratches though.

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Saturday, May 27, 2017 - 08:01 AM UTC

I have my eye on a Revell PBY just in-case this SR does not want to cooperate.

Bob

If it aint broke dont fix it.

Nordrhein-Westfalen, Germany

Joined: March 22, 2015

KitMaker: 671 posts

AeroScale: 614 posts

Posted: Saturday, May 27, 2017 - 02:36 PM UTC

Bob: Keep my fingers crossed for Your resin bird. But, a PBY will be nice, too!

Chris: Thank´s a lot for the clue. I will try this!

Oliver

On the desk: Probably a Panzer III.

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Saturday, May 27, 2017 - 08:02 PM UTC

If it aint broke dont fix it.

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Sunday, May 28, 2017 - 02:49 AM UTC

[quote]after todays try at attaching the fuselage together I will go with the Revell PBY. Here are some photos of this dog, I still may send it to you Jonothan

][quote]

No No No.... don't give up yet!! Just get out your nippers and trim that plastic away, then heat up some water and mold that hull back into shape-- you can do it-- we lurkers have faith in you!

VR, Russ

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Sunday, May 28, 2017 - 04:23 AM UTC

Russ, I will give it a try. I will get the PBY anyway just incase the hull melts from my efforts.

If it aint broke dont fix it.

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Sunday, May 28, 2017 - 10:54 AM UTC

Bob,

What are you using for glue? Cyanoacrylate is really the best glue for resin-- and it will bind styrene to resin as well. it looks like you're using something else? No other glue will really work on resin, as it's surface is impervious to most styrene cements. Don't try to submerge the styrene parts in hot water-- you can damage them through shrinkage or warping. A good two part epoxy could also be used, but it will take longer to cure, will be less rigid, as well as requiring more clean up. I recommend Bob Smith Industries (BSI) Thin and gap filling super glues they have light blue and pink caps. With thier accelerator it gives instant bonds. I also recommend a good set of adjustable plastic clamps, although rubber bands work, they may leave marks that need to be cleaned up.

VR, Russ

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Sunday, May 28, 2017 - 06:44 PM UTC

Russ, I use Bob Smith CA. I am now going with the REVELL PBY and shelve the SR for another day when I feel like working with the resin. Thanks for he encouragement.

Bob

If it aint broke dont fix it.

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Sunday, May 28, 2017 - 07:56 PM UTC

Quoted Text

Russ, I use Bob Smith CA. I am now going with the REVELL PBY and shelve the SR for another day when I feel like working with the resin. Thanks for he encouragement.

Bob

That's BSI glue at the bow? It looks very gooey-- I've never had that happen before. Do you have any idea what caused it to separate like that?

VR, Russ

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Sunday, May 28, 2017 - 08:20 PM UTC

It is the thick and has been sitting out for a while, I don't put them in the fridge. I after holding the part my fingers became tired and let up on the pressure. Ive put the SR away till another day and ordered a REVELL PBY to complete this campaign.

Bob

If it aint broke dont fix it.

#259

Massachusetts, United States

Joined: October 23, 2011

KitMaker: 2,265 posts

AeroScale: 1,715 posts

Posted: Monday, May 29, 2017 - 07:56 PM UTC

So be it. I totally sympathize. I have more than one box on my shelves with a kit in that state....

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Tuesday, May 30, 2017 - 04:37 AM UTC

Quoted Text

So be it. I totally sympathize. I have more than one box on my shelves with a kit in that state....

Jonothan, Ill trade you one of your

kits for mine

Bob

If it aint broke dont fix it.

Indre-et-Loire, France

Joined: May 23, 2011

KitMaker: 651 posts

AeroScale: 181 posts

Posted: Tuesday, May 30, 2017 - 01:51 PM UTC

WOW, did you find any solution since you posted theese pics ??? I wish you good luck anyway !

cheers

nico

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Tuesday, May 30, 2017 - 08:59 PM UTC

Nicolas, no solution found at this time. Will keep the kit on the shelf until much later or I purchase another to start with some experience from this present kit to guide with the next.

My Revell PBY should be here this Saturday so I can start anew.

Bob

If it aint broke dont fix it.

Washington, United States

Joined: March 15, 2009

KitMaker: 3,670 posts

AeroScale: 833 posts

Posted: Tuesday, May 30, 2017 - 09:56 PM UTC

Bob,

Just curious if you've tried to use CA accelerator on the Saunders-Roe hull glue job-- I can't really tell from the photos if you have a warp problem or a bad glue problem-- it kind of looks like both to me. If it's a warp problem and the mating surfaces can be squeezed together, an accelerator will give you an almost instant bond. If it's not possible to get the mating surfaces together, you'll need to heat the hull in hot water (just shy of boiling) and bend them into shape- or trim the floor until it fits the hull-- but if it's just a slight bend in the resin and you can get the mating surface together, CA should hold it in place. I know you are moving on to a PBY, but finishing a resin kit is a great reward in itself too-- why not do both?

VR, Russ

Texas, United States

Joined: February 22, 2008

KitMaker: 5,026 posts

AeroScale: 2,811 posts

Posted: Wednesday, May 31, 2017 - 02:41 AM UTC

Russ,I have not tried the accelerator and with my hands full of airplane I probably could not attempt any. While this is not my first resin or multi media kit, it was not approached correctly. So I will purchase another to build using this attempt as a guide

to really take time to make sure of fit before I assemble.

Bob

If it aint broke dont fix it.

Maybe I should send it to you Jonathan