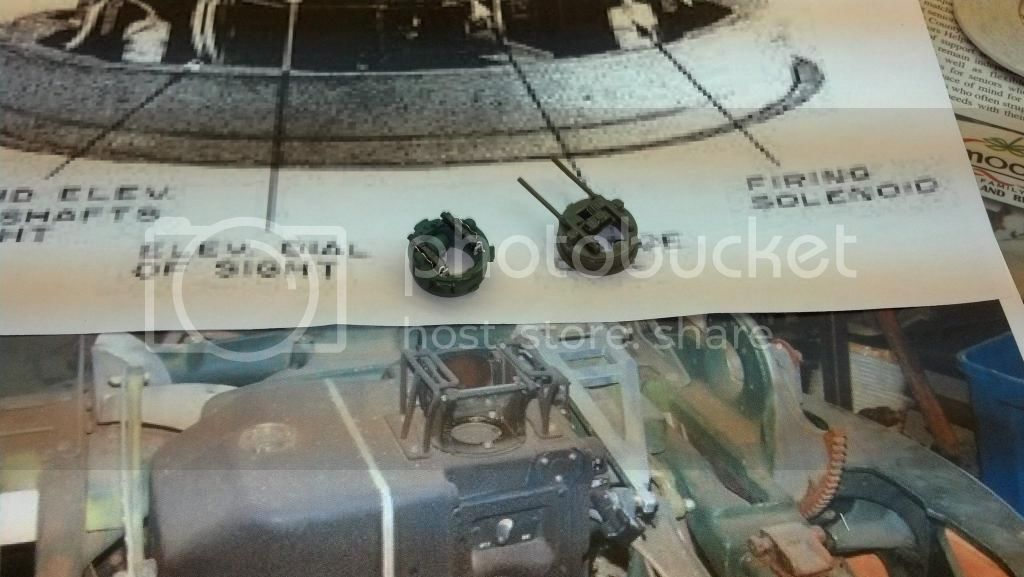

You can see how I modified the shapeless kit gunsight -- from the rear. I didn't realize until the picture was taken that the data plate was a bit off-center. I will replace it with a smaller decal later, and also show you what the front and top of the sight look like after modifications.

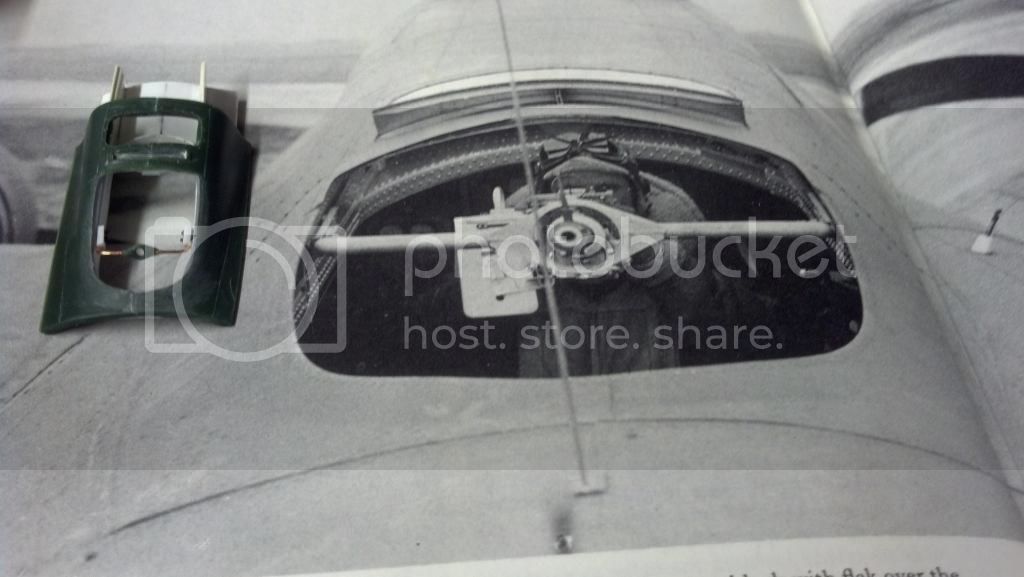

Going back to the main picture, I removed the center from the top turret ring, where the guns, gun feeds and sight were. The resin gun bases pictured are from the Verlinden set: I already drilled out the holes in front for the Karaya metal barrels and blast tubes.

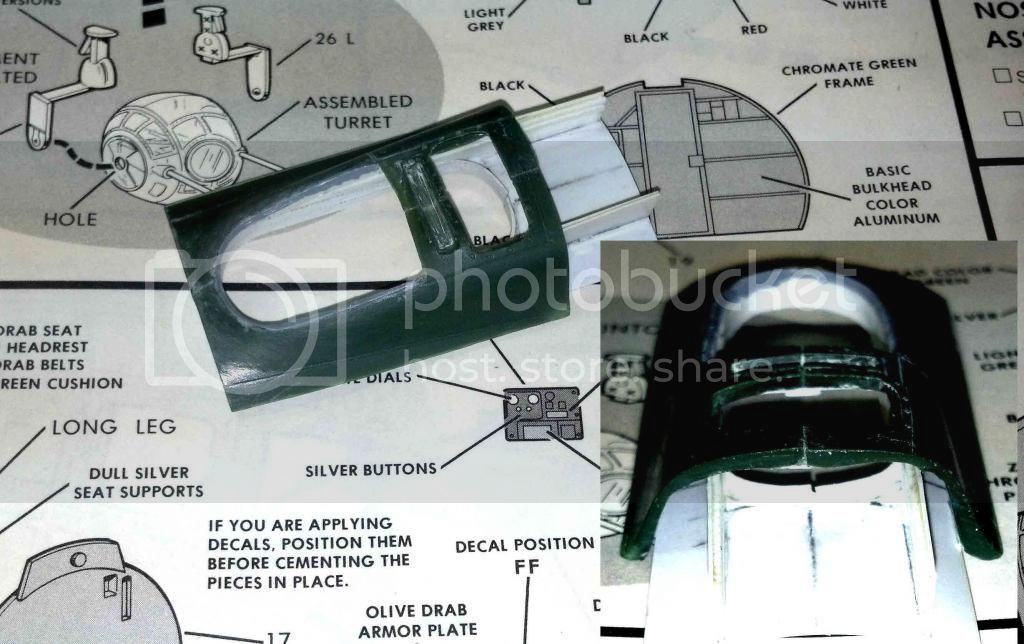

Next, take a look at the unpainted turret dome and compare it to the real thing, which is the last picture in the prior post. This part is from Bill Koster's excellent "B-17F Nose Job" set. It doesn't look like much unpainted, but when you compare it to the Revell kit part in the picture -- the one I built in the 1980s -- you can see how very different it is. Here is a better picture of Koster's work from his instructions. If you want to do an accurate B-17F, the Koster part is a must!

To free the dome from the vacuform backing, I cut it out leaving a 1/4 inch border around the edge. (None of that scoring at a 45 degree angle around the base for me: too dangerous.) Instead I put the part on a flat sheet of 320 grit sandpaper and sanded the base away with a light circular motion. After a while it thins to the point where it just cracks and falls away from the part. I do like this method.

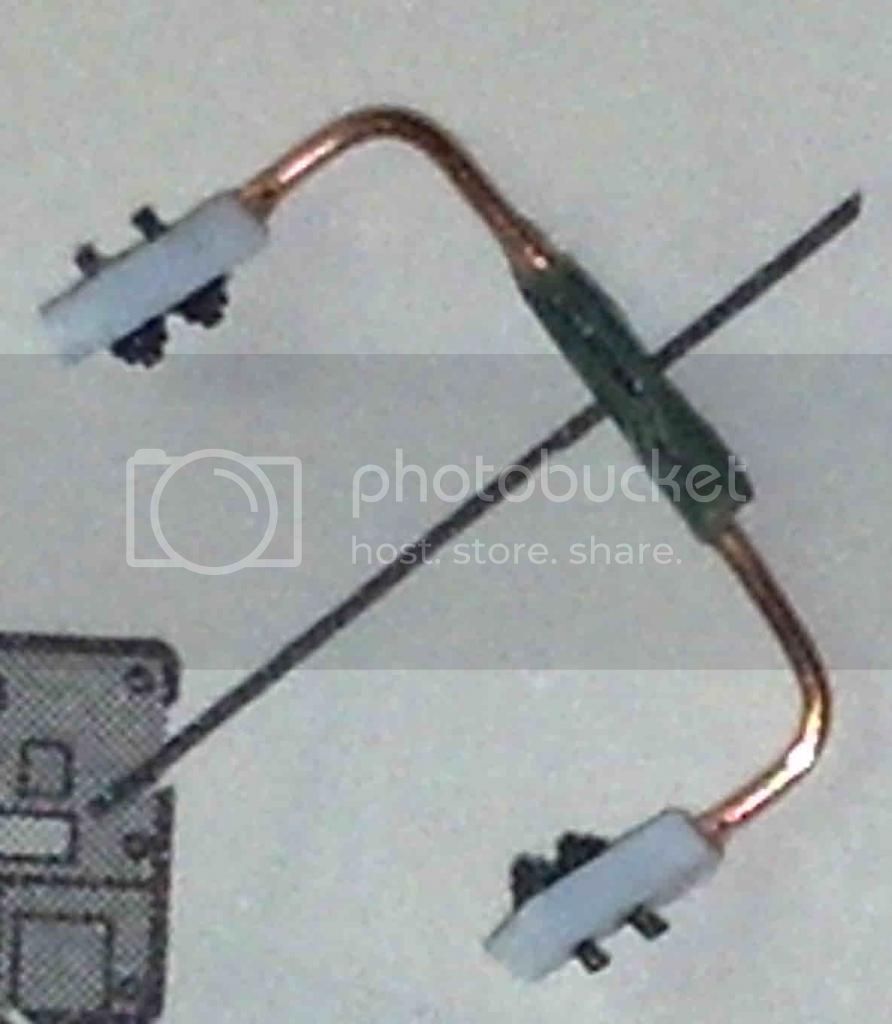

Later this week I am meeting my friend from North Carolina and we will do some work on the two biggest challenges in the build. The first is the radio room roof assembly around the rear hatch that houses the .50 cal with a sliding U-shaped bracket. The structure is totally missing from the Revell kit. See below.

We are also going to work on the ball turret, outside and inside. Outside we have to add semicircles to the sides of the ball and restructure the holding bracket. Compare the two photos below:

Above is the turret that "Luscious Lady" carried. What follows is the much simplified exterior side structure carried on later B-17 ball turrets.

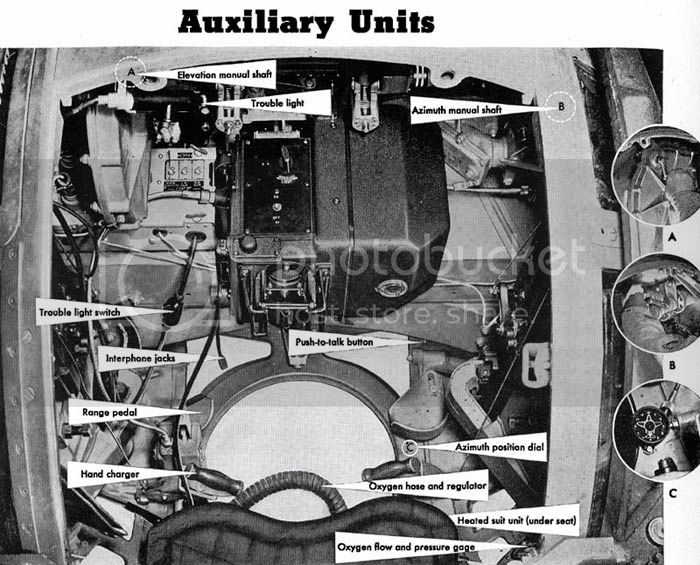

Finally, we will consider adding some detail to the interior of the ball.

Stay tuned!