Hi folks. I have FINALLY got a chance to throw some paint at my build. Nothing special just yet, some RLM in the office and front wheel well and NMF in the pods and main gear wells. I will post some pics once I get the detail painting and PE belts added in so it actually looks interesting !

In the meantime, how about a quick in-Campaign tutorial???

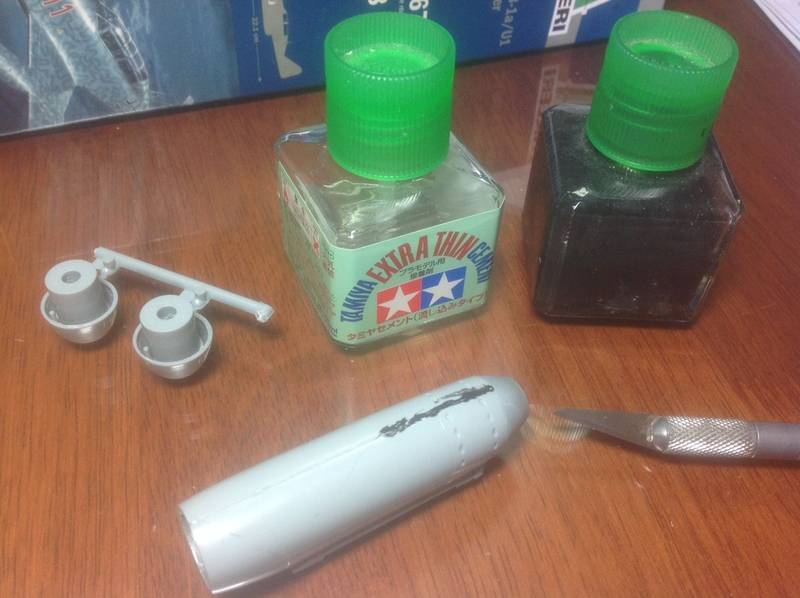

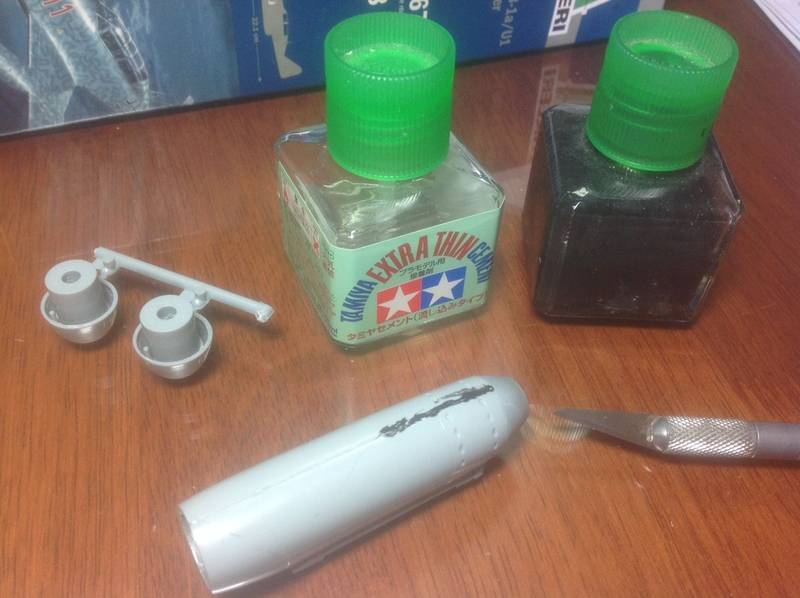

I use Tamiya Extra-Thin Cement pretty much exclusively on my builds. I read in a couple of forums about folks making their own cement/putty/gap-filler using this product and old sprue material, so I gave it a try and have been using it for a while now with good results. In this first pic you can see the bottle of Cement, and beside it an old bottle which I threw a pile of old black sprue pieces in (from my 1/48 Monogram P-61 build if I remember correctly) and left for a few hours to dissolve. The good thing about this product, if you can call it that, is that if you find it too thin just throw some more sprue in, and if you find it too thick to apply just add some more cement! I chose to use black sprue so that it would stand out against the grey styrene of my current builds. I will make some grey in my next batch to use on a few dark green and black kits that I have in the stash. You can use the brush attached to the bottle lid to apply the filler, or I use a toothpick sometimes for small spots like ejector pin marks or ham-fisted knife divots (I'm good at making those!)

In this second and third pic I have dabbed a line right along the bottom join of the engine pods, enough so that it is slightly raised above the join. The join was not too bad on this pod, but on the second it was quite gappy. Using this type of product you can build up layers and fill quite a gap because it actually dissolves and bonds with the kit parts rather than just adhering to the surface.

When I got back from work tonight it was quite literally 5 minutes sanding with my weapons of choice (Sanding Sticks, Flexible Sanding Pads and my favourite Flex-I-File) while the kettle boiled, and the joins are smoothed out flush with the pod halves.

I love the Flex-I-File because it can be used very accurately and not remove part details.

Sorry for the long-winded post, I just thought this would be of interest to a few of you who hadn't seen it done before.

Cheers, D